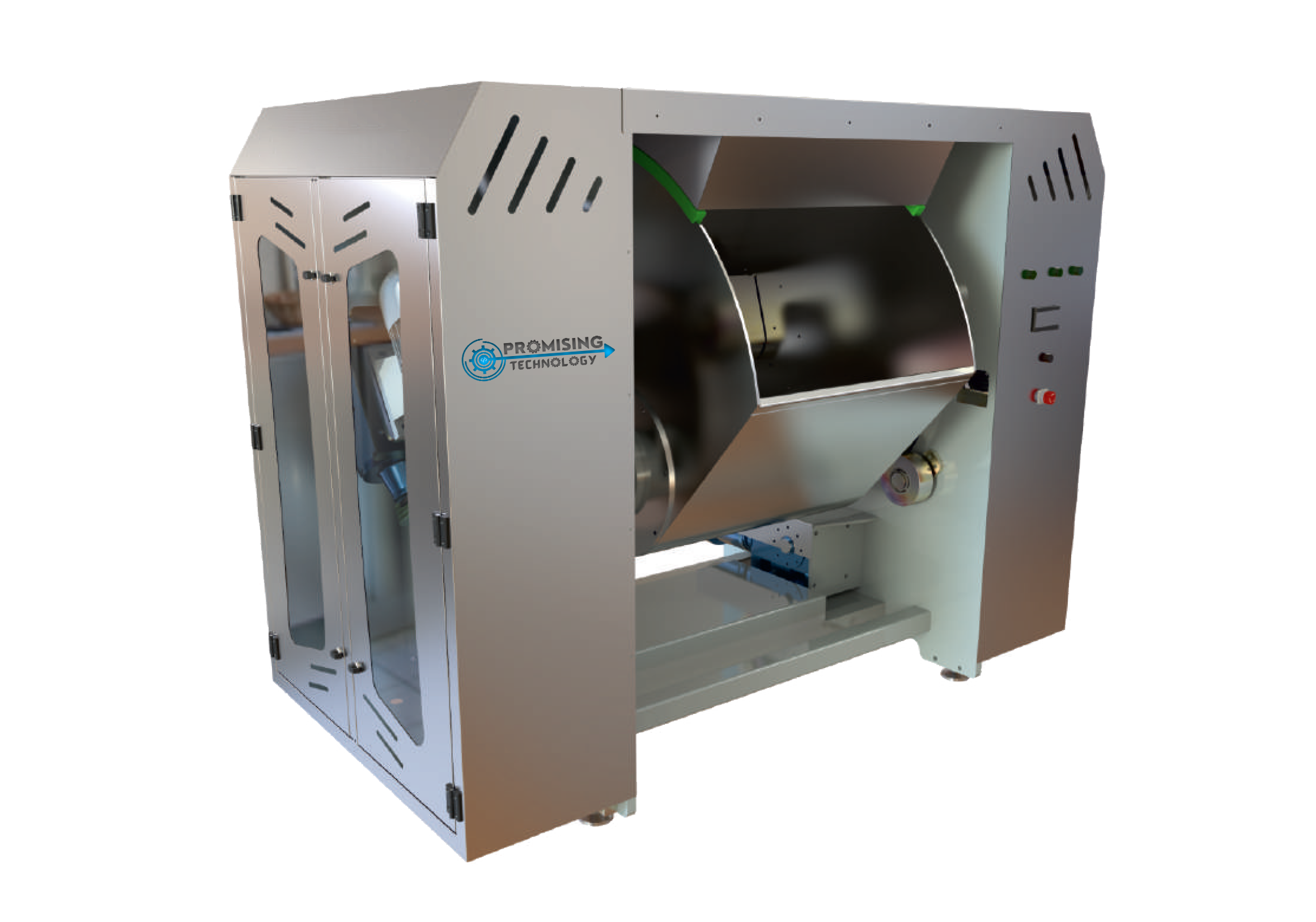

• 500Kg (est.600Lt) Mixing Capacities • Adjustable 3-Time Homogeneous Mixing • Prescription Record • Adjustable Mixing Speed with driver • Controlled via PLC Touch Screen • Ready top inlets to automatic feding • Hydraulic Lifting • Dough Discharge Jog (Sigma Arm Reverse Turn) • Dough Tank Overturn Safety • Easy Cleanable Dough Tank • Service Door Safety Sensors • Efficient Electric Motor and Reducer • Electrical Motor: 37kw (Mixer Arm) + 2,2kW (Batch Tilt) - 380V 50Hz • Mixer Weight: (est2) 5300Kg • Stainless Steel Double Jacket Dough Tank (for Cold and Water Connection) • Optional Loadcell Configuration

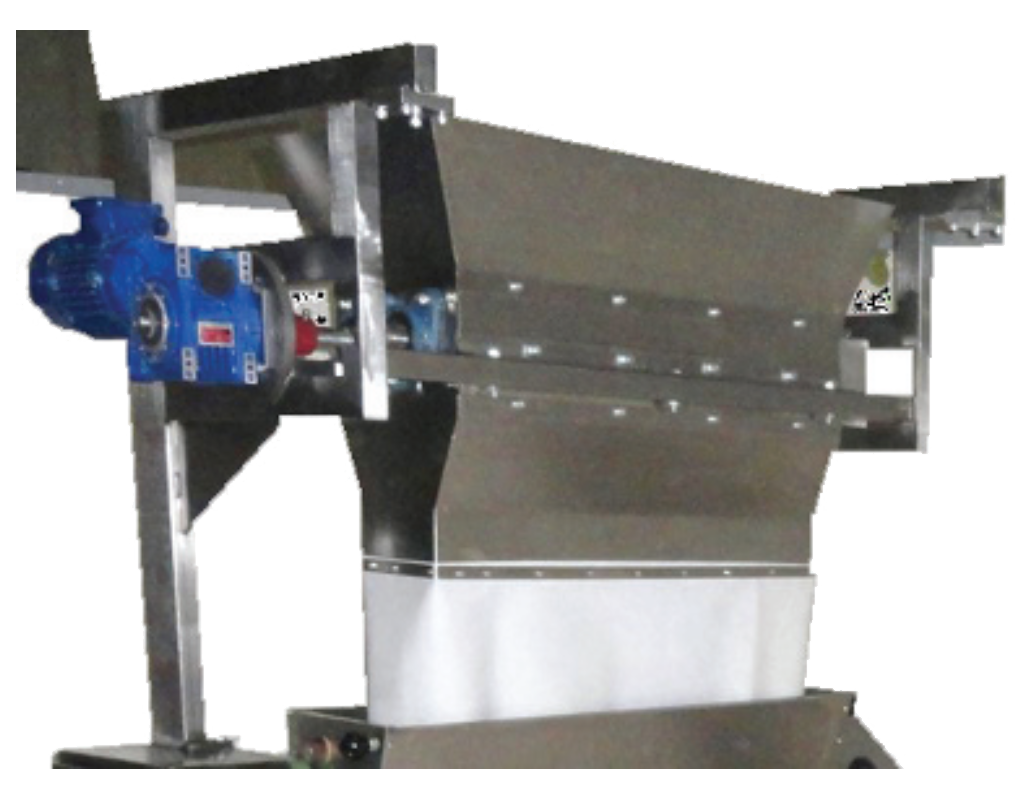

• Prepared Dough will be split up and convey to the necessary point • It communicates via the level sensor located on the Sheeter Hopper or rotary Hopper • With the signal from the sensor, the feeder cuts the required amount of dough and transmits it on the palette conveyor • It passes on the Pallet conveyor to he dough conveyor • Polyurethane belt used at the feeder bottom conveyor • Inclining Pallet Belt Conveys dough with durable profile sections • Feeder and Pallet belt work synchronously with Sensors • The Feeder Dough Tank iss feed by hand or by Optional Additional hydraulic dough car lift. • Dough Tank Capacity: (Est.) 800 Lt

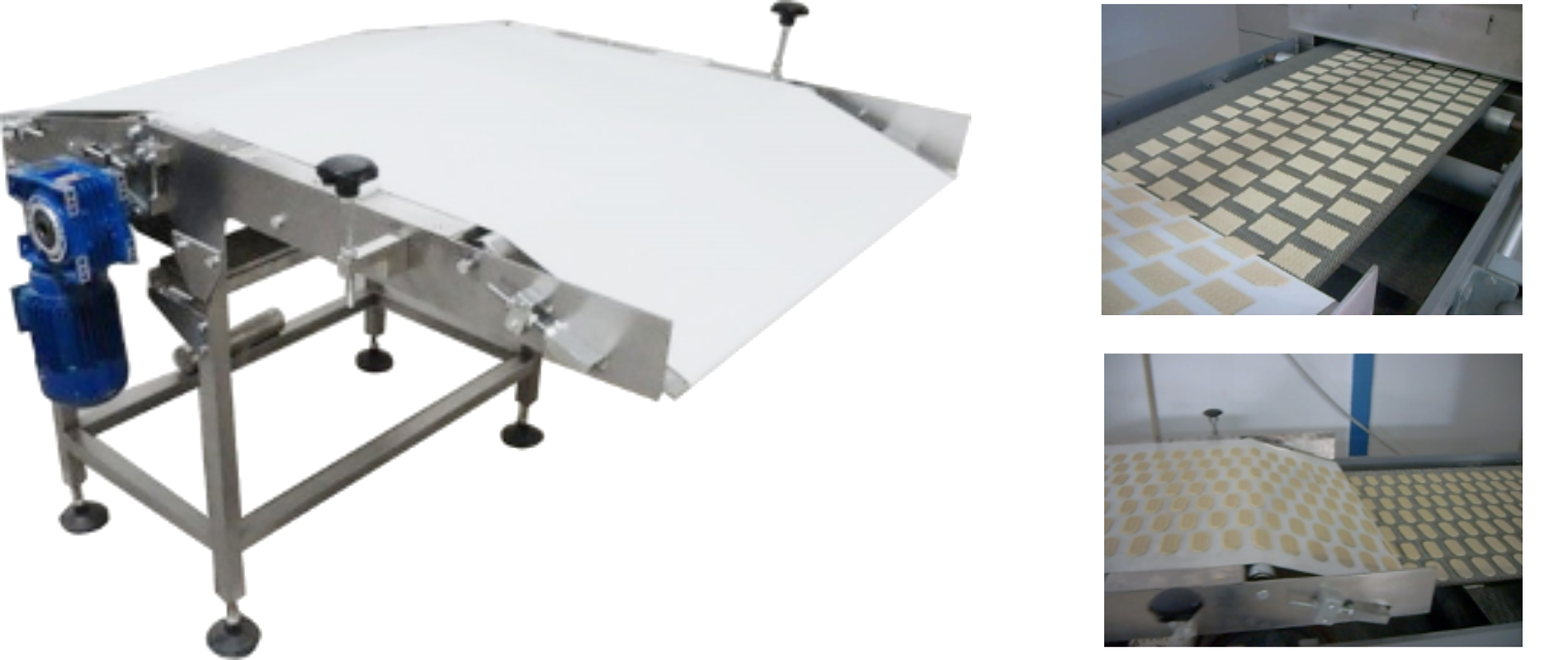

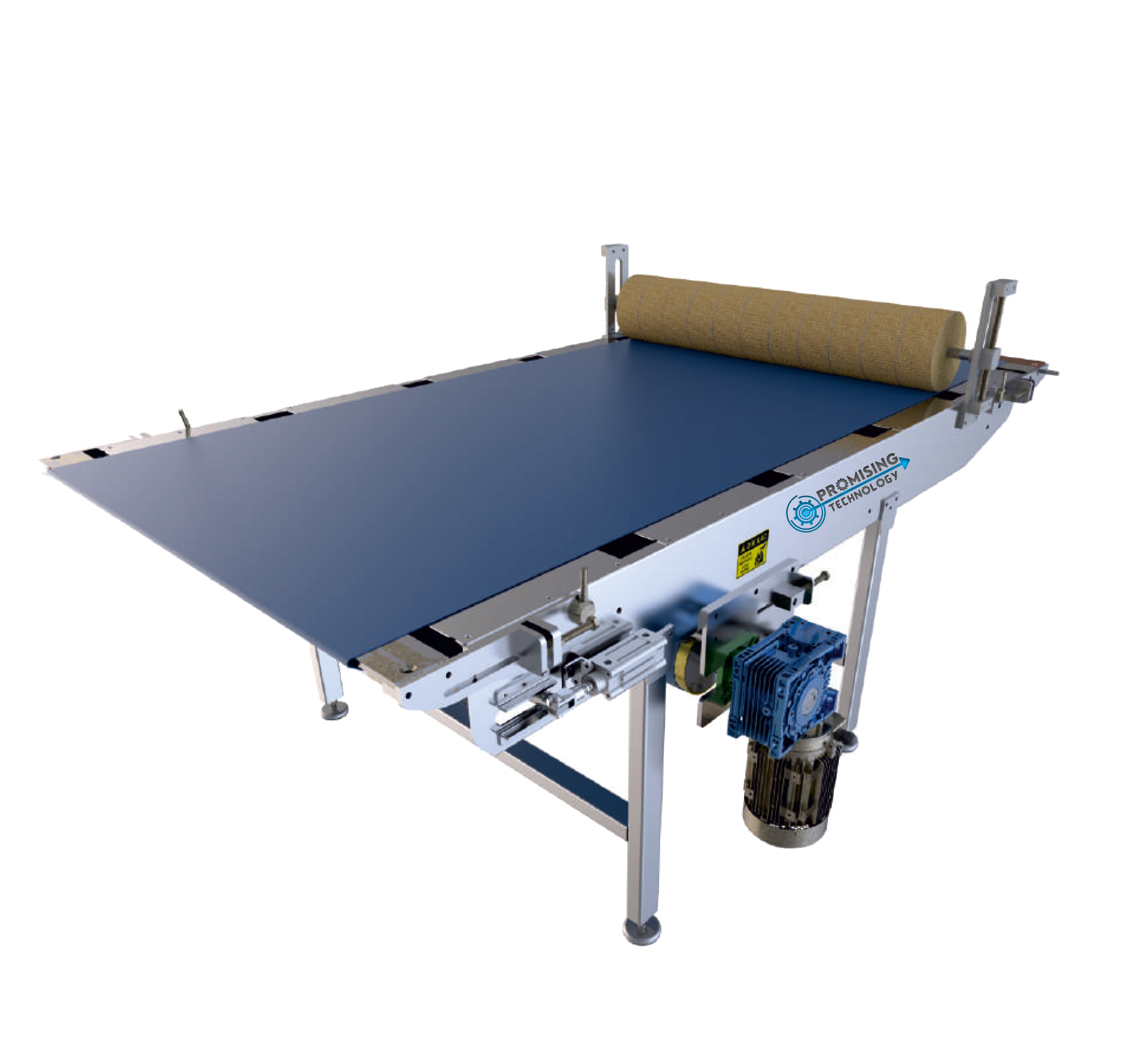

• Automatic dough feeding system. • Endless Polyurethane conveyor band. • Conveyor belt endless changeable. • Belt cleaning knife.

• Stainless steel dough tank • Dough thickness control Manual or Optional with PLC Control • Electronic speed control • Conveyor belt Endless Polyurethane and Easy Changeable • Belt tracking device • Three roll sheeter •Rolls made of Hardened and Polished Steel • Cylinder cleaning knife • Drive: Electric Motor with Reducer • If the Dough preparation is made in a upper level, the Ceiling Sheeter will be used. • It can work Synchronously with other equipments on the line.

• Conveyed Dough from the Sheeter will be Thinned between Gauge Roll Cylinders • Gauge Rolls machines consist of two or three groups. The dough is gradually thinned in each pass • Dough thickness control Manual orOptional with PLC Control • Gauge Roll Cylinders are specially made, Surface Hardened and polished • Conveying belts are polyurethane • Conveyor Belt Speed can be adjusted electronically • It can work synchronously with other equipment on the line

• Biscuit Dough will be Shredded for feeding the Rotary Machine • Opposite Pin installed Drums revelation shreds the soft dough • Stainless steel body • Drive: Electric Motor with Reducer • It can work Synchrously with other equipments on the line

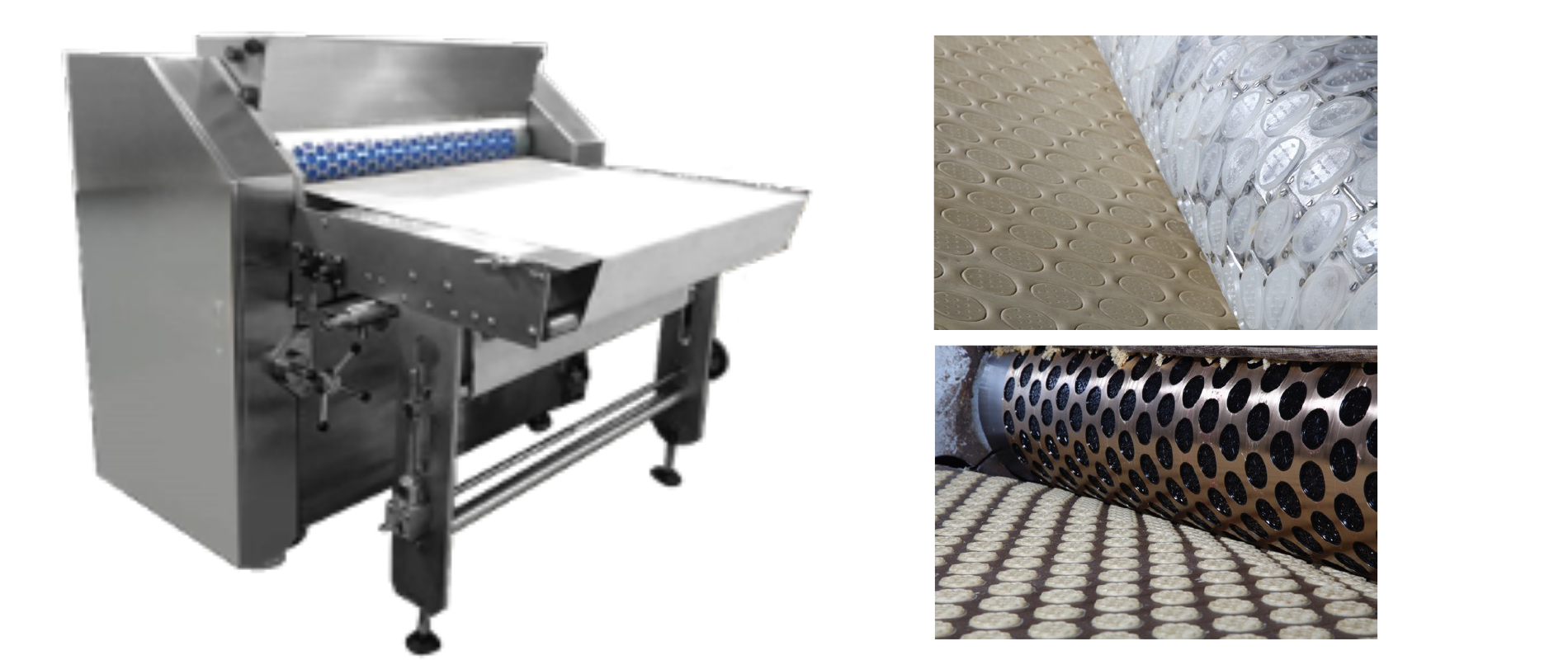

• Rotary Cutting (With additional Gauge Roll Group) and Moulding on the same machine • Easy Roll Changeable • Sheeter Roll, Rotary Roll and endless conveyor roll • Electronic speed control • Has a Rubber press roll with Rubber roll pressure adjustment • Belt tracking device • Sheeter roll dough thickness adjustment • Sheeter roll drive, Rotary Roll drive and Endless belt drive with gearmotor • Belt cleaning knife • Biscuit Moulds are sold seperated • Endless Special Woven Cotton belt easy changeable, Is used in biscuit production. Has no seam. Its warp threads are continuous. Therefore, homogeneous thickness on the belt is obtained. In its warp, 100% polyamid is used. In its weft, cotton with 50% polyamid is used. 20 warp threads in 1 cm. exist. Endurability against streching is good. Its thickness is 2.0mm. The tissue created during weaving by putting warp and weft threads together includes tiny pits. These serve the purpose of vacuum rooms while the biscuit dough sticks to the surface of the belt. In this type of belt, the mentioned vacuum rooms are deep. Thus the surface of the belt looks notched. The biscuit dough is in direct contact with the polyamid surface created by warp threads. With the cotton weft and the quality of oil sucking a new and comfortable working condition on the belt surface is created. No treatment is required when the belt is installed into production for the first time by the user. Occasionally, for its working harmoniously with the dough, it needs to be treated by exposing steam. During its healty life, its reaction against holding the excess dough on the belt surface is positive. Prevents dough loss. Is suitable for both rotative and cutting processes. Its working life is in average 3-6 months. This term extends or becomes shorter according to the speed of the user, the type of the dough or the need of tightness required while working.

• Hard Biscuit Dough Scraps will be conveyed to reducing the loss ofdough to the Sheeter for using in the continious production • Stainless Steel Body • Endless PVC conveyor belt • Conveyor belt easy changeable • Belt tracking deviceDrive: Electric Motor with Reducer • It can work Synchrously with other equipments on the line

• Used to take off moulded Biscuit dough to transfer to the oven • Conveyor belt is used as required: Polyurethane or textile belt • Conveyor Belt Speed can be adjusted electronically • It can work synchronously with other equipment on the line.

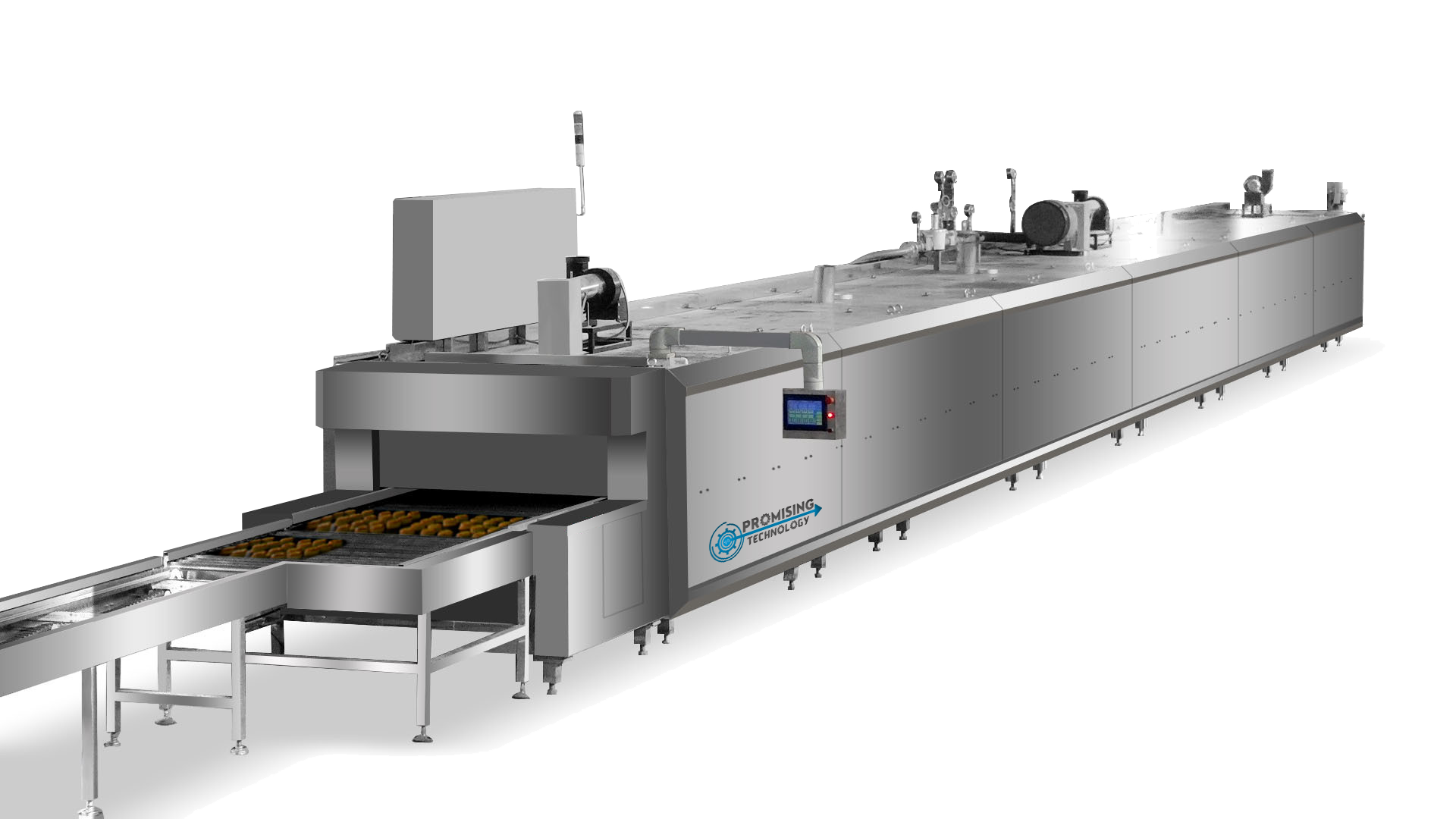

• 1,2x60mt oven Baking lenght. • Wire Mesh Belt. • Electrical power supply: 380 V 50 Hz • Auxiliary voltage: 24 V. • Control side: left or right • Heating system: indirect • Biscuit oven body Steel (Paint Coated) • Useful baking length 60 meters • Oven belt 1,22m • Useful baking width 1,18meters • Input table length 2 meters est. • Output table length 4,7 meters est. • Total oven length 51,7 meters est • Natural Gas • Number of zones: 4 • Baking time Minimum 2,5 - 7 minutes • Electronic speed control. • Belt tracking device. • Type Wiremesh " .." • Weight per sq. meter .. Kg • Drive cylinder diameter 900 mm • Tension cylinder diameter 900 mm • Belt drive: AC Motor with reducer • Transmission: Chain • Emergency drive: Chain • Automatic firing system. • PID heat control system. Digital temperature control. (Zone and fire room) • Chimneys and moisture exhaust are adjustable • Baking room max 350°C. Fire room Max 500°C • Cleaning device for wire-mesh • Synchronized with speed of existing dough machines. • Total oven capacity 350.000x4=1400.000 kCal. • Out side plank will be oven Stainles Steel (CrNi 430). • All manual heat adjutsment will be have set positions. • Motor will be Yılmaz • Electrical material will be Omron or equilevant • One observation window. • Biscuit takeoff knife ( at end of the oven) will have adjustment. • Special Stone Wool used for Heat insulation • Special High Heat Fiber Blankets are used for Burning room insulation • There is an Free section along the Tunnel Oven for easy cleaning to ensure hygenie.

• Used to take off Biscuits from the oven belt (wire mesh belt or textile belt can be used). • Conveyor belt is used as required, wire mesh belt band or textile belt. • Conveyor Belt Speed can be adjusted electronically. • It can work synchronously with other equipment on the line.

• Before passing onto the cooling conveyor, the biscuits are arranged vertically in rows. • The vertically stacked biscuits move towards the packing machines on the cooling belt. • Gear motor Drive • Synchronious speed control • Before passing onto the cooling conveyor, the biscuits are arranged vertically in rows • The vertically stacked biscuits move towards the packing machines on the cooling belt • Cooling belt, Wire Mesh Belt, Polyurethane Beltor Modular Belt can be used • For smallcracker products, Bypass is located on the Stacker • The length of the cooling belt will be at least as long as the oven length

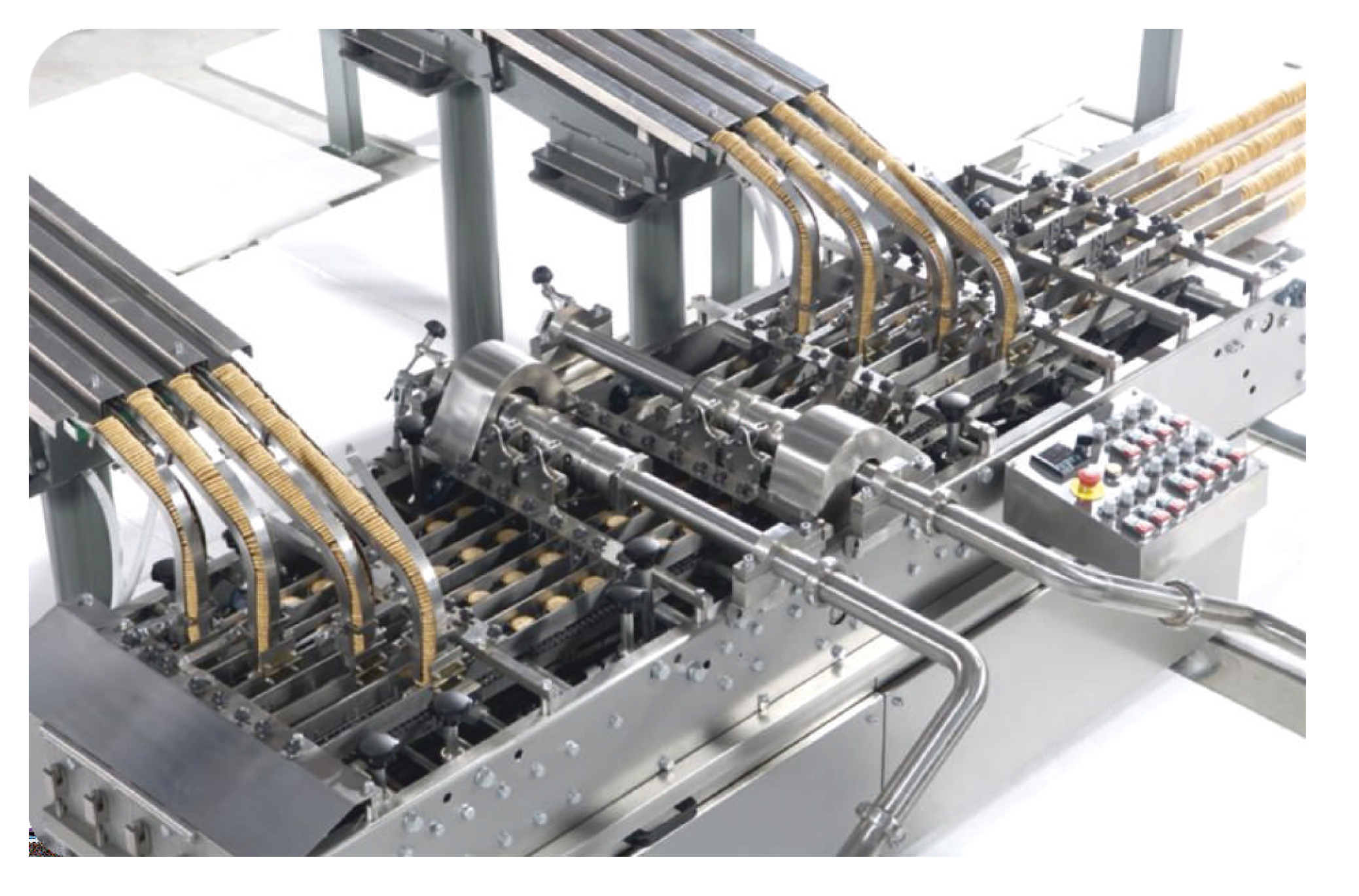

• Cream Sandwich Biscuit Machine its used to produce Sandwich biscuits. • Sandwiching type: Duplex Biscuittypes can be produced. • Components: Main Machine, Cream Stock+Cream Pump, Biscuitnflownbelt, Electric Panel. • Creaming Heads Cream out put will be designed as request. (onepoint, twopointorfour Point output) • Cream Stock System: 2 Pc’sTanks(240 Kg / Tank Capacity) • Cream Stock Feeding: 2 Pc’s Pumps • System Biscuitfeed is Manual Feed, Transfer can be preferably with vibration flowor with belt conveyor rows. • Speed controlled with Electronic controlled Motors. • Can be synchronized with the accom panying machines

• Its been used to prepare for the cream which used in sadwich biscuit production • Capacity 100Lt • Mixer Drum and Stock Tank made from Stainless Steel • Manual indegredient Feed.

• Crystal sugar is grinded to powder sugar • The machine is of the pitched disc type and consists of a rotary rotor and fixed stator discs • The machine consists of 3 main groups: body, crystal sugar storage, powder sugar bunker • Body is made of spheroidal casting material to prevent vibration • Crystal sugar will be feed manually • During machines work, inside the body creates vacuum and the crystal sugar absorbs from the reservoir. • Powdered particles are transferred to powder sugar bunker • To prevent Powder sugar dusting, there are filters on the powder sugar bunker • The powdered sugar is 30 ÷ 35 microns thick.

• Non-standard products of the production will be Grind it into pieces and biscuit flour • Biscuit mill 150Kg/Hour • Stainless steel body • Steel body • Hammer type grinding • Optional: Auger Feeding

It is a machine that makes fats to liquid for use in preparation of wafer, chocolate, caramel. There are serpentines in which hot water is circulated. The melted oil can be easily transferred to the desired machine by means of a pump.

It is a tank where preliminary of nougat batter is made and prepared homogeneously for cooking. It can circulate in itself with the help of a pump. Outer section of tank is heat-walled. The product recipe that can be adjusted from the control panel automatically adjusts the amount of product to be transferred from the tank or to be taken into the tank by means of loadcell and electronic valves. The inner part of the tank and the pipe connections can be easily washed and drained by the rotating water heads inside the boilers.

It’s tank that is used for stocking of ready to cook nougat batter. When the product is desired to be used, it is transferred to the cooking unit by means of pumps. Mixers are available in order to protect homogenous structure. The product recipe that can be adjusted from the control panel automatically adjusts the amount of product to be transferred from the tank or to be taken into the tank by means of loadcell and electronic valves. The inner part of the tank and the pipe connections can be easily washed and drained by the rotating water heads inside the boilers. Reservoirs is heat-walled.