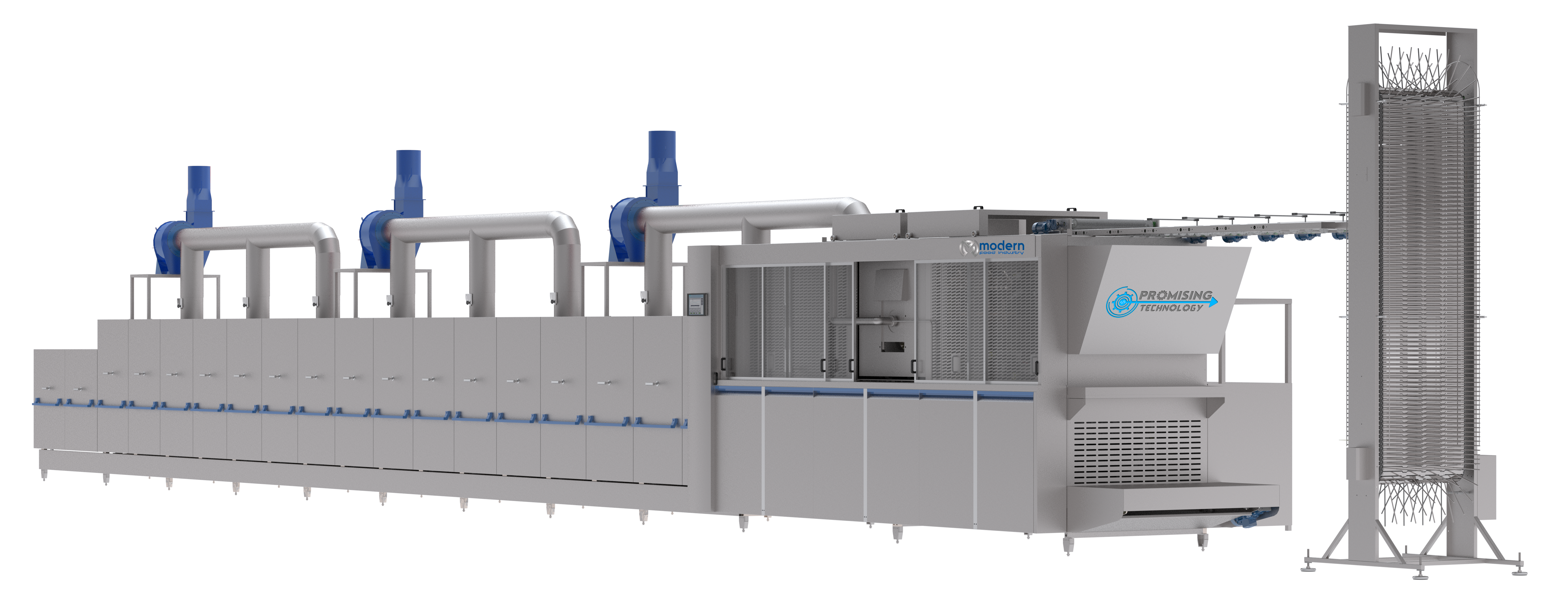

It’s used for production of wafer sheet. It can produce the size of 280x380 , 290x470 – 350x500 as per the request. The standarts of wafer moulds can be manufactured 24-36-40-60-72-90 number. Normal and cambered wafer sheets can be produced. It can work with the consumption of LPG and Natural Gas. Aimed minimum gas consumption with new ignition system. All types of control concerning oven can be done via touch-screen PLC Panel. - Moulds can be manufactured the size of 280x380, 290x470, 350x500 as per request. - Mould can be opened 45 degree . The sections where lock , hinge and carrying arms located is bushed. - Cambered wafer sheet can be produced as per request

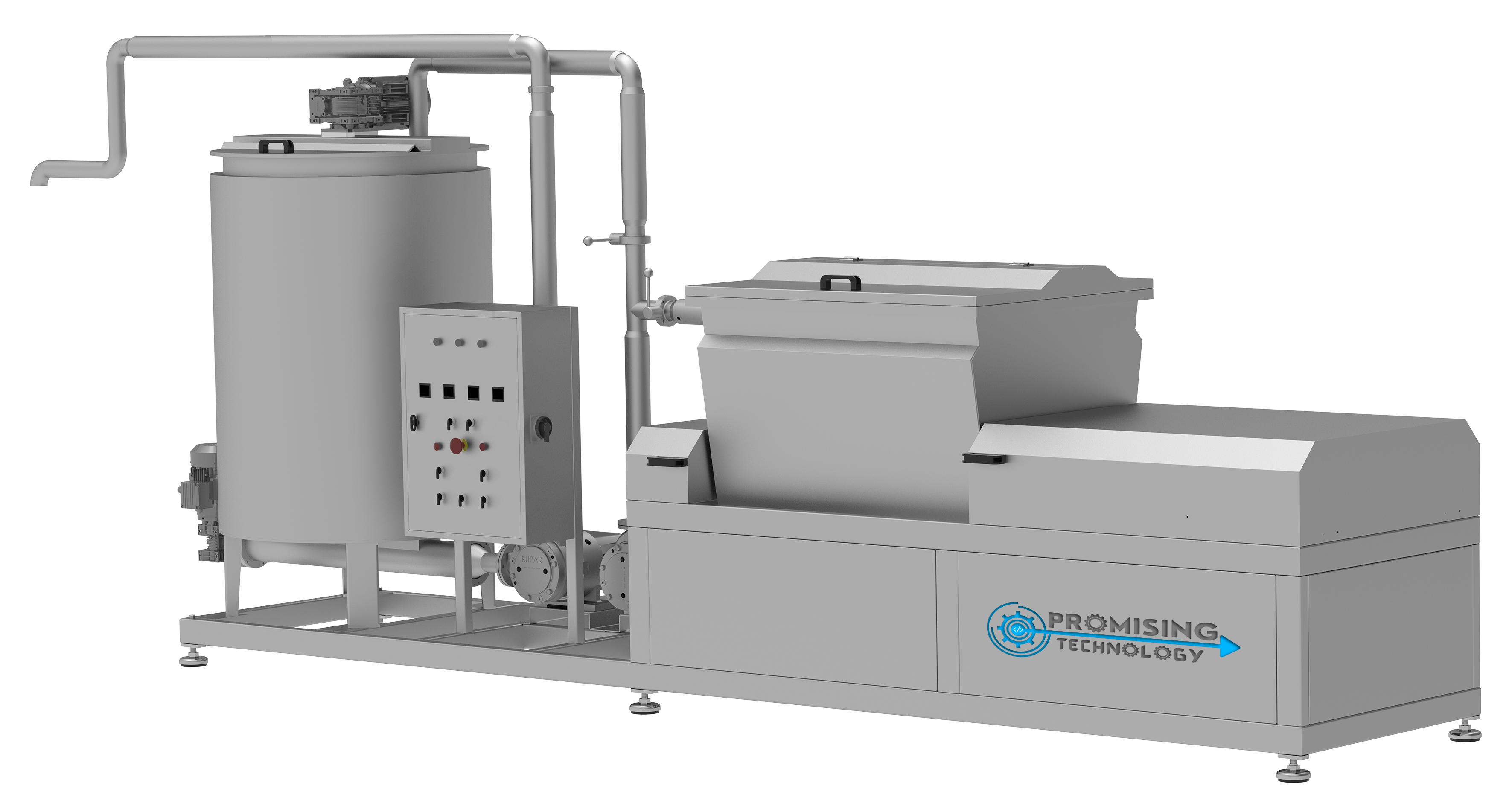

Batter mixer manufactured with stock tank. Ready to process batter which is prepared with equipped special mixing system in the batter mixer keep waiting in stock tank for transferring to wafer baking oven. It works with turbo mixing system. In-line plants , automatic bypass system are available.

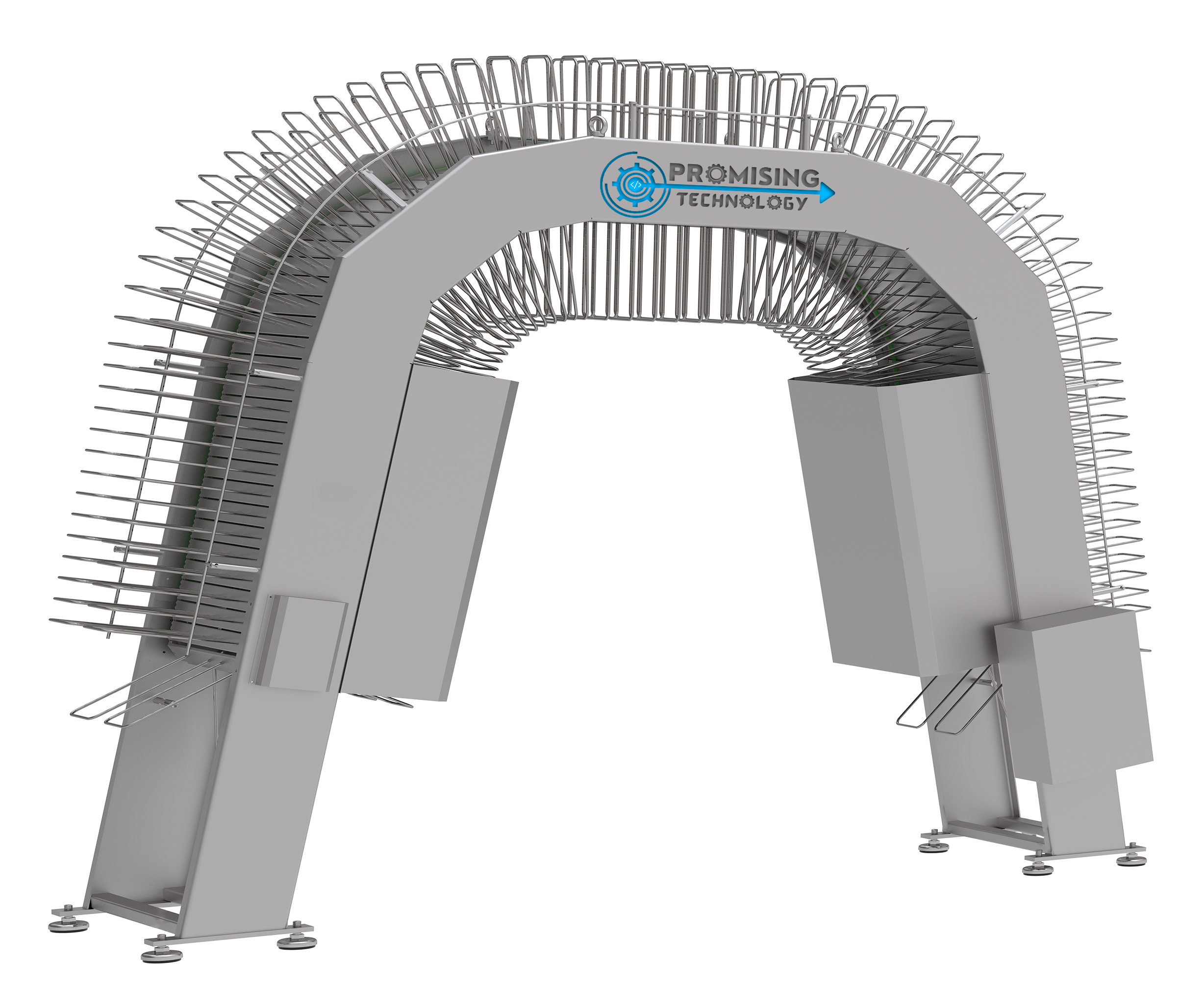

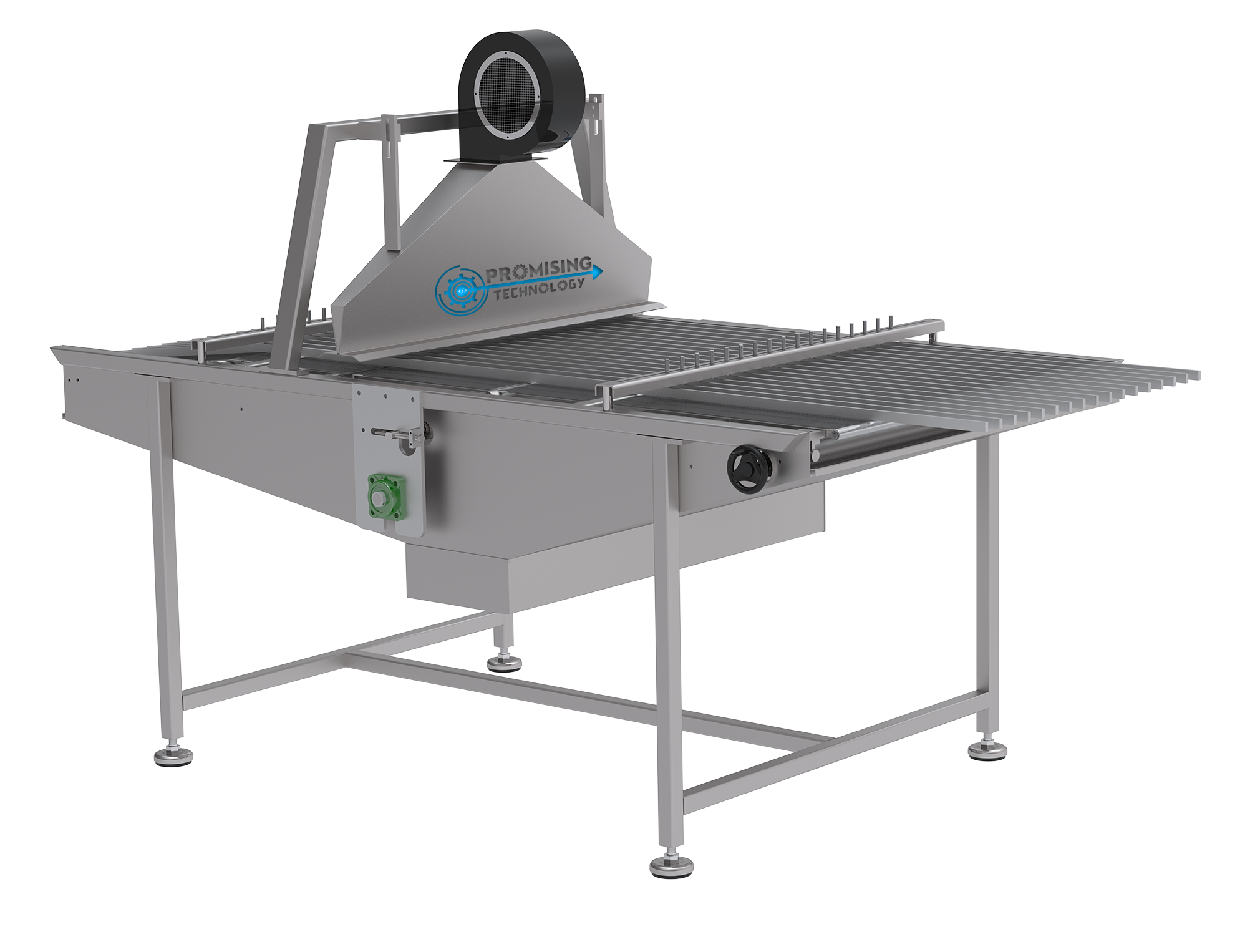

It’s used for decreasing the temperature of wafer sheet in normal weather condition and combing the wafer sheet which is not compatible out.

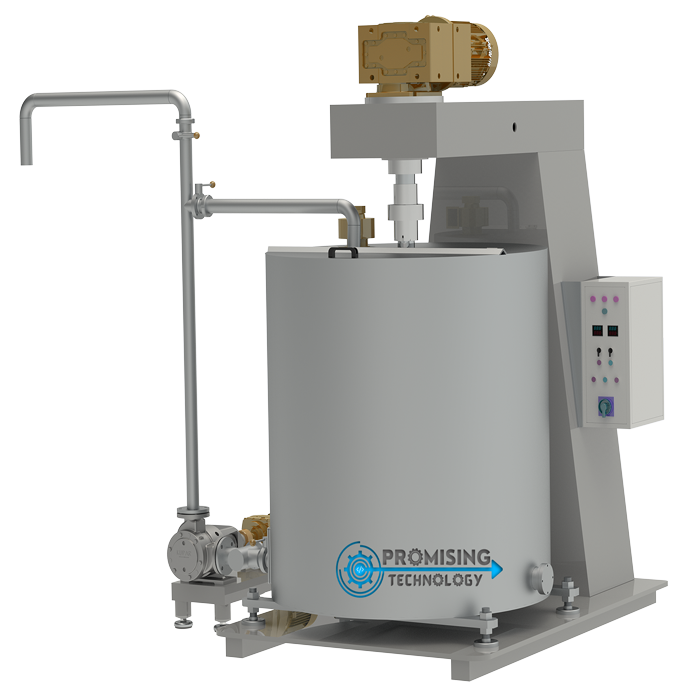

It’s a machine is used for preparation of cream which is used spreading interface of the wafer sheet as homogeneously. Anchors and scramblers are available. Compatible for preparing solid and liquid cream. Prepared product is transferred t o stock tank on the side via pumps.

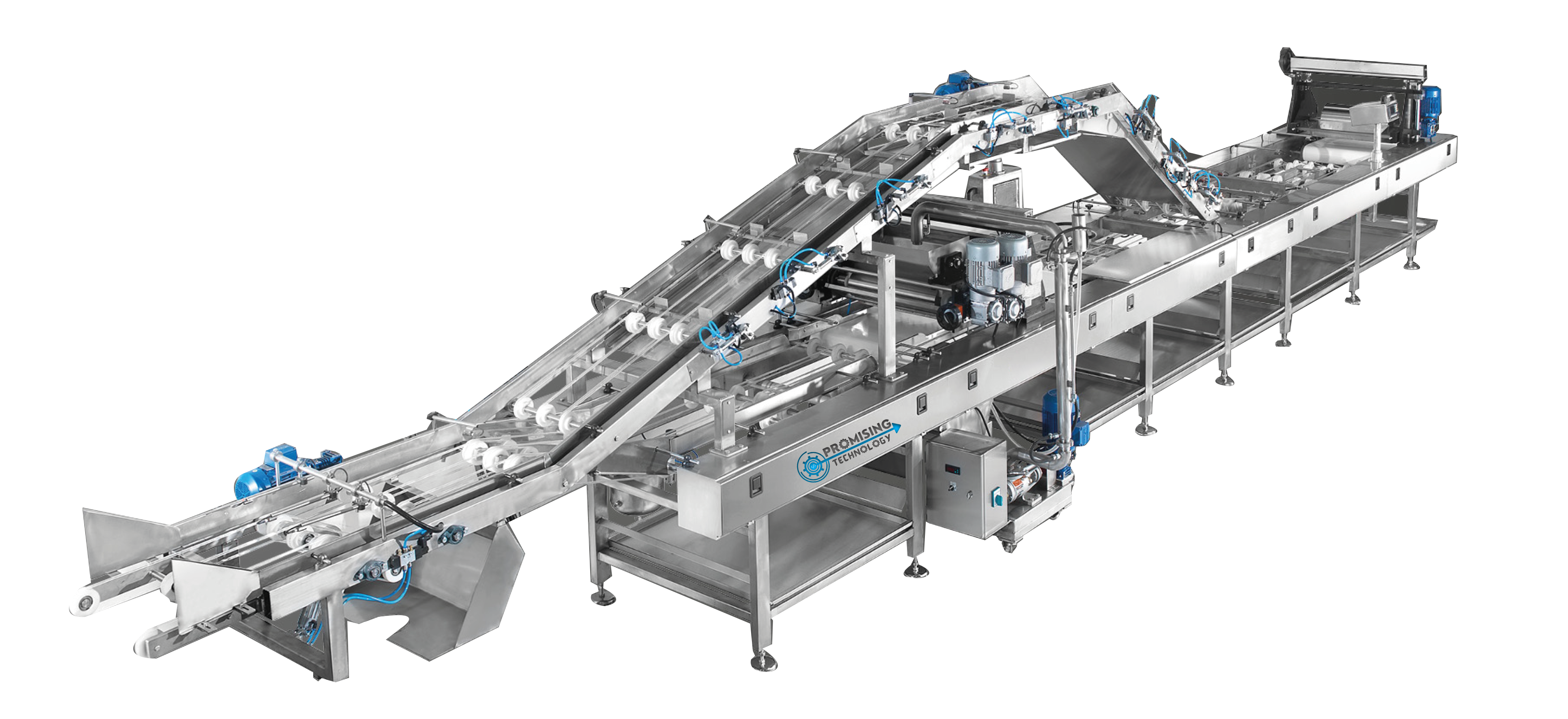

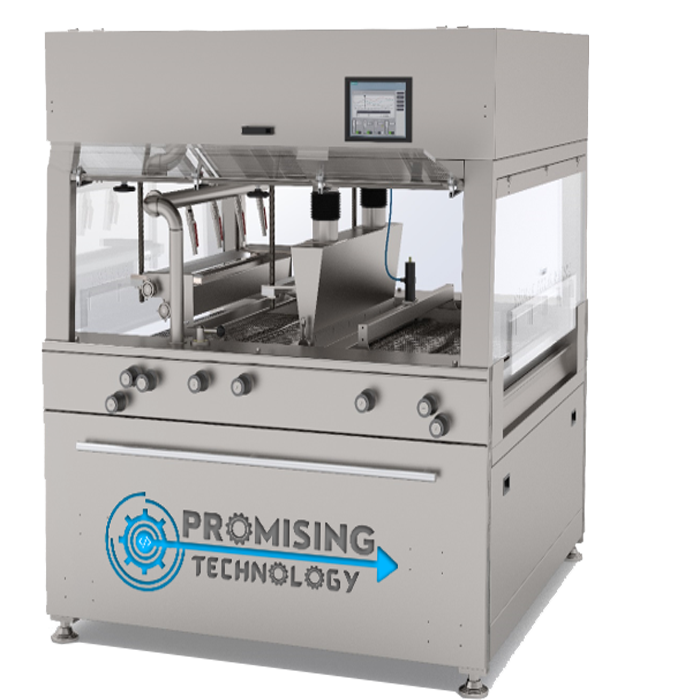

It’s providing the spreading of the cream which is prepared in the cream preparation mixer to interface of the wafer sheets. Sheet and layer pcs can be adjusted as per request. Walled cream reservoir and recirculation system located bottom of spreading reservoir are available and it works synchronously with machine. It is possible to reduce the errors to minimum levels with the weighing group which is synchronized with the machine and located at the output part of the machine. It can be easily controlled from the touch panel on the machine.

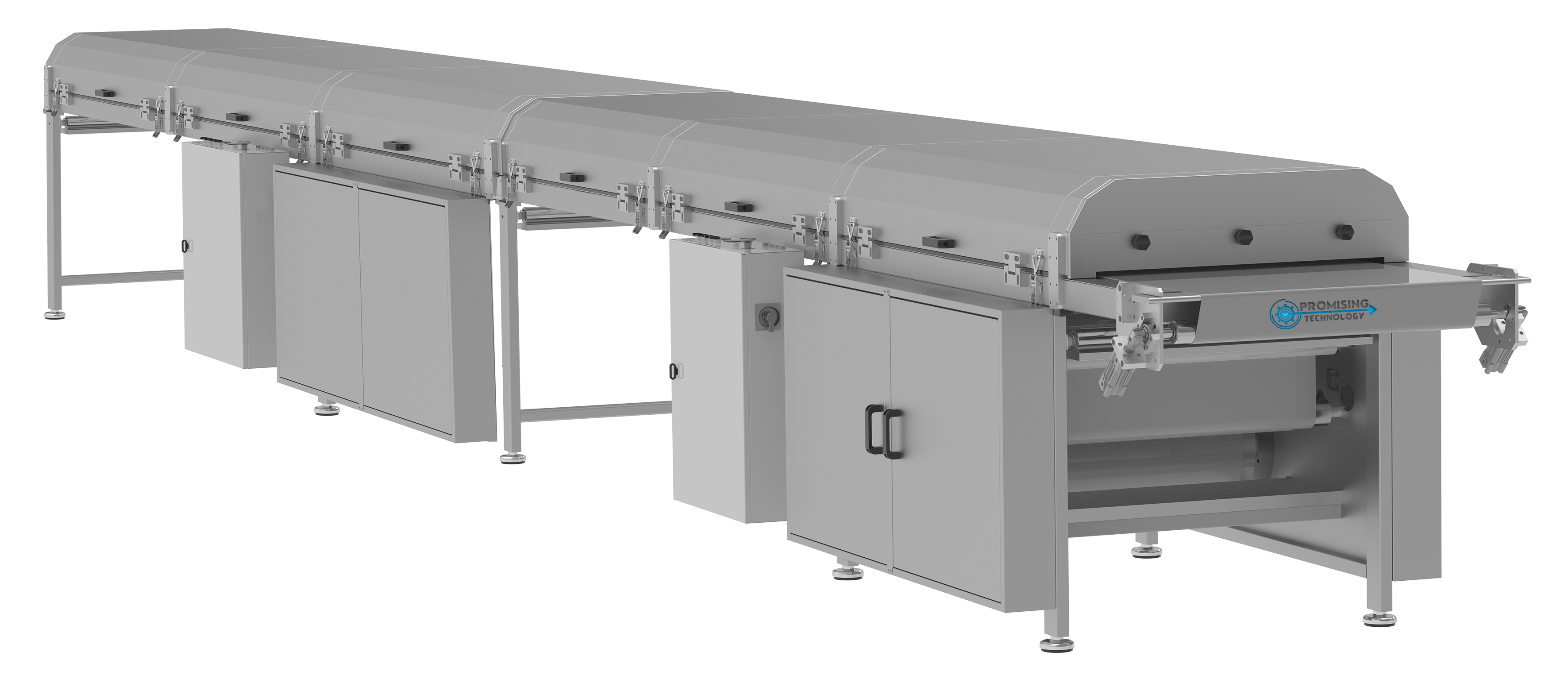

It’s a machine using for reducing certain temperature of the wafer block which is spreading process completed. It can be adjusted specially as for plant capacity. The cooling capacity starts from 18.000 kcal/h and varies as for capacity. System works as stopand- go. Via sensors , aut omatic removal is available.

It is a machine for used cutting to cooled and creamed wafers by means of steel blades in order to bring them to final product dimensions. Cutting dimensions can be adjusted as per desired request. The production process continues uninterruptedly thanks to the automatic feeding system on it. Block cutting process can be done as single or multiple. It is possible to make bidirectional cutting in two different sizes. It can be easily controlled from the touch panel on the machine.

It is the machine used to grind the unused side edge parts of the wafer blocks cut in the wafer cutting machine during the operation of the production line and to re-mix the cream into the cream preparation. The particle of the wafer are grinded properly by means of helix and steel blades inside the machine. It’s compatible for grinding wafer, cookies and cake particle.

It is a sieve type mill used to convert crystal sugar into powdered sugar for use in the production line. So as to provide convenience for user , sugar reservoir and helix are available. Sifter changing and cleaning process is designed for providing convenience to users. The particle size varies between at least 40 microns and at most 70 microns.

It is the machine used to recess the gap between the wafers which cut at the finished product dimensions in the wafer cutting machine. Aligns the products before entering the chocolate enrobing machine. The wafers aligned in seperation table is seperated from each other by means of recess band. It works synchronized with wafer cutting machine and chocolate enrober.

It’s used for cleaning of burr and crumb of the wafer coming from seperation table via air blowing. It works synchronized with wafer cutting machine and chocolate enrober.

It is a machine that makes fats to liquid for use in preparation of wafer, chocolate, caramel. There are serpentines in which hot water is circulated. The melted oil can be easily transferred to the desired machine by means of a pump.

It’s a boiler that all the raw materials needed for the chocolate mixture are collected. It aut omatically adjusts the amount of product to be taken into the boiler with the help of loadcell and electronic valves. The reservoir is heat-walled and the hot water is continuously circulated by means of a circulation pump. The mixers are driven by two separate motors. It can transfer the prepared chocolate mixture to the chocolate mixer by means of pumps.

It is a machine used to make thin and mix the chocolate mixture to a more homogeneous structure. The reservoir is heat-walled and the hot water is continuously circulated by means of a circulation pump. The product is accessed to the desired fineness with the help of steel balls in the reservoir. Strainer and magnets are available at the reservoir outlet. The product can circulate by means of a pump. The prepared chocolate mixture can be transferred to the chocolate stock tank by means of pumps.

It is the tank used to stock the chocolate prepared in the chocolate mixer. There is a continuous mixer system in order to keep the homogenous structure of the chocolate waiting for use. If desired, it can be transferred by means of pumps. The reservoir is heat-walled and the hot water is continuously circulated by means of a circulation pump. It can be manufactured in different capacities as per the request.

It is a machine using for enrobing chocolate to products such as wafers, cakes and biscuits. It is designed according to work both real and cocoline chocolate enrobing. Machine is designed adjustable, if required , just bottom , just top and completely enrobing options can be done. Bandwidth can be manufactured in desired dimensions. It can be easily controlled from the touch panel on the machine.

It is a machine used to cool the products coming out of chocolate enrobing machine. Watery, airy cooling and rollbond systems are available. Adjustable to desired lengths. It is very easy to clean thanks to the caps that can be opened in both directions.

It’s used for production of wafer sheet. It can produce the size of 350X700 , 350x800 as per the request. It’s a high capacity and 120 moulds as a standard. It’s compatible consumption of natural gas. Wafer sheet removal process is done with vacuum system. Vacuum system works synchronously with moulds. All types of control concerning oven can be done via touch-screen PLC Panel. Moulds can be manufactured the size of 350x700, 350x800 as per request. Moulds can be opened 120 degree. Heat-proof bearings are available in the section of hinge and carrying arms located.

It is a machine used t o stabilize the moisture range of wafer sheet coming out of sheet cooler. Works synchronously with sheet cooler and spreading machine. It’s designed special as for the capacity of wafer production line. Outer section of machine is isolated. It can be controlled handily via the touch-screen panel on the machine.

It’s a machine using for reducing certain temperature of the wafer block which is spreading process completed. It can be adjusted specially as for plant capacity. The cooling capacity starts from 18.000 kcal/h and varies as for capacity. Product are carried by means of special wireband which is manufactured of steel applicable for food regulation. Band speed works synchronized with production line spe ed.

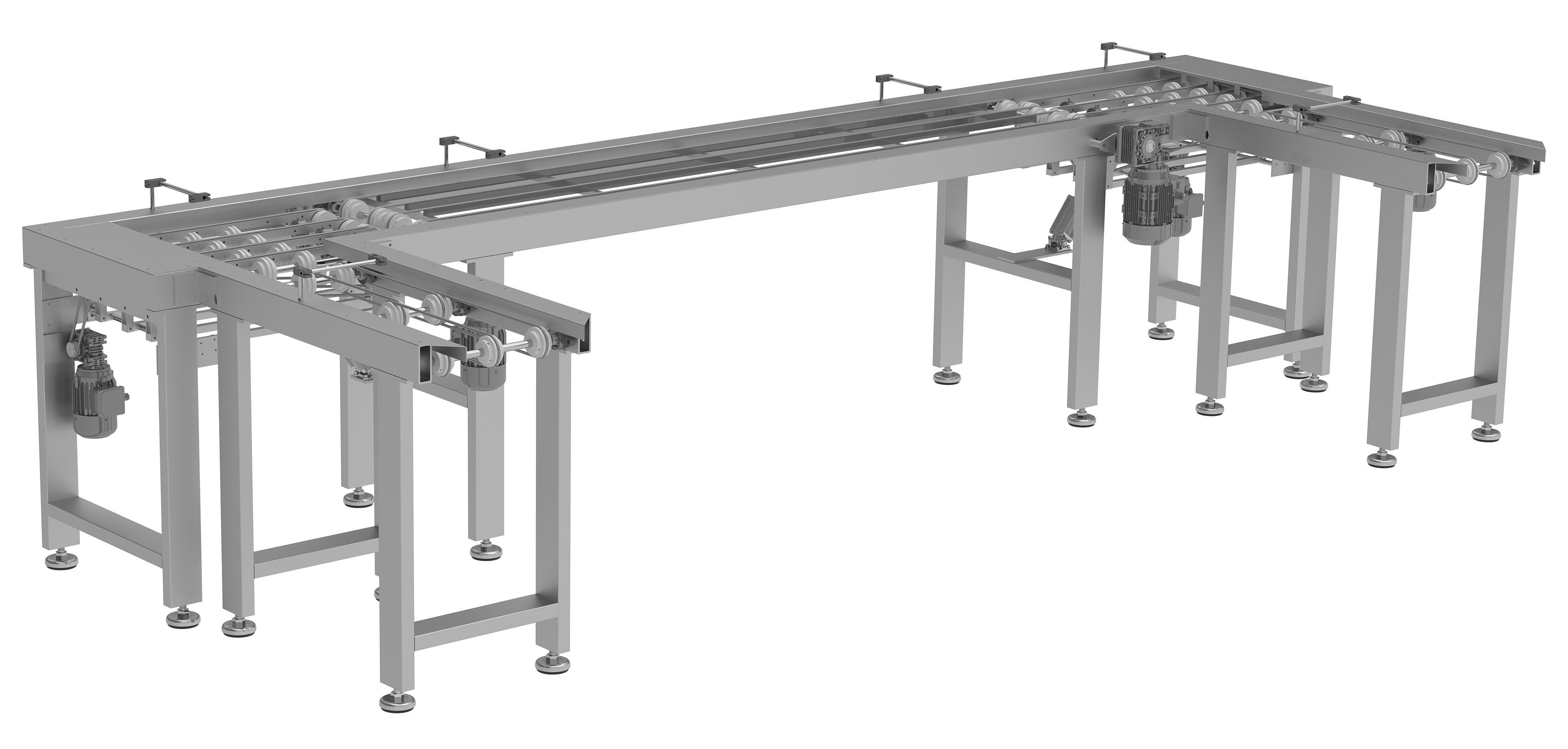

Generally used for rotating of wafer production line as a parallel in case of the area of factory is narrow. Wafer blocks can change the direction easily on the band by means of sensors. Polyurethane belt compatible for food regulation is used on the machine.