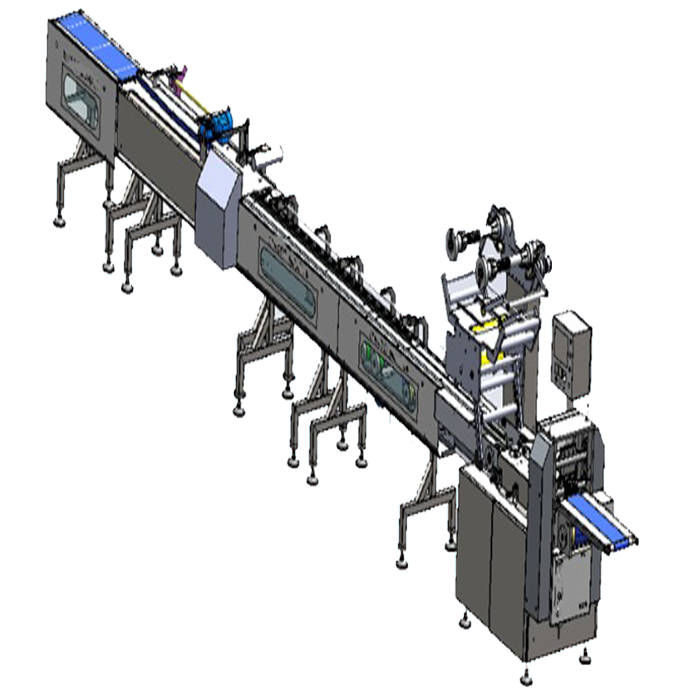

Packaging Machine will have a capacity of 400 rpm for cake. For enrobed products the

ambient temperature must be +20° C.

General Characteristics

•4 groups longitudinal sealing with disc (1 drawing,2 sealing,1 directing)

•A dissolver roll driven with servo motor driven for precise paper control

•Special, modular jaw group changeable according to the product and packing material

•A distinctive design which allows the operator interventions from both sides offering a

hygiene and ergonomic working environment.

• All driving and moving systems and power board; they are all installed in the process

line with insulation.

•Designed for easy belt interchange and aligning works

•Thanks to the scales all settings are done easily and in repeatable way

•On all belts there are steel blades which can be mechanically set.

•Thanks to the removable rolls an easier cleaning is provided.

•There are stainless steel pans beneath the conveyors.

•Maintenance and cleaning is easy and fast.

•It provides fast transition for different dimensions and shapes.

•Automatic cellophane transfer is available.

•All parts in contact with the product are stainless steel.

•3 Dimensional product control is available and non-conform

products are excluded from the system.

•Empty/double/attached packages are excluded.

Our company transforms standard packaging

machines with mechanical length control

into machines that meet the needs of small-scale

manufacturers and high-volume manufacturers with

the addition of today’s technology products.

Benefits

• High flexibility: You can adjust the package size, cutting

place, speed of bonding discs and jaw on the t ouch screen.

• Fast product switching: The transition time from one product to

another can be easily made from the touch screen.

• High efficiency: Thanks to the precision and stability at the cutting

point of the product, it is ensured that wastage is reduced and productivity

is increased.

• Product Quality: Thanks to the precision and stability at the product cutting

point, the package quality increases significantly.

General features

• High quality, excellent packages

Quick transition for dif ferent sizes and shapes

• Easy adaptation to systems

Display showing machine status, malfunctions, production information and alarms

PC supported motion control unit

Color photocell for photocell cutting

• I can change product sizes quickly by changing just a few parts

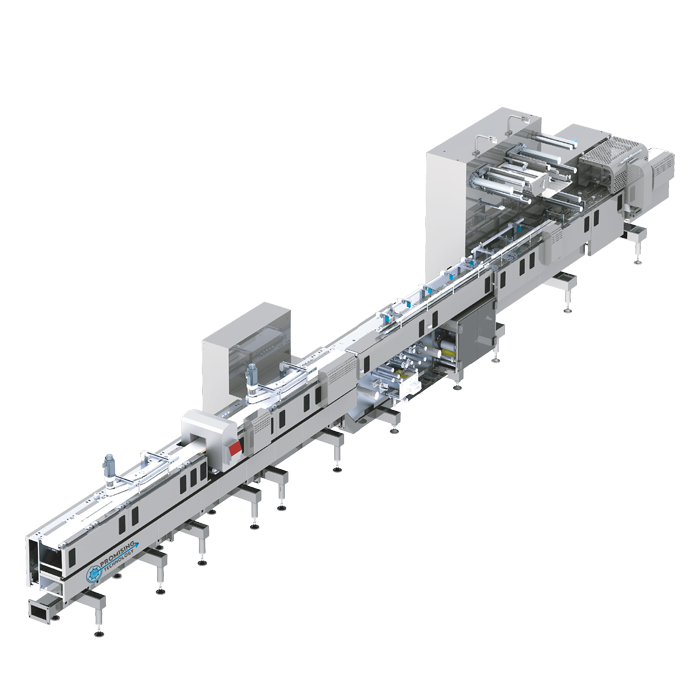

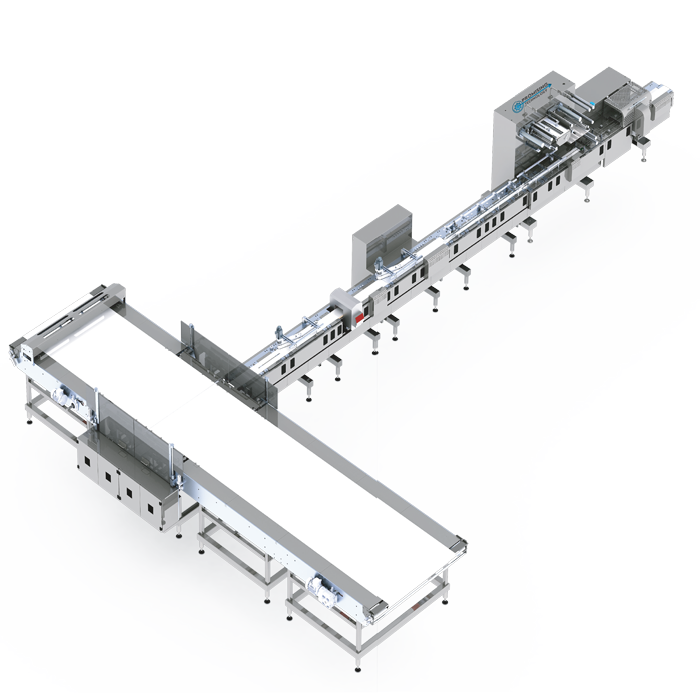

It is a modular structure designed for the automatic distributi- on of chocolate bars, cakes, wafers, biscuits and other

similar products coming in rows from the production line.

• Product Types: Chocolate bars, layer cakes, wafers, biscuits and other similar products either enrobed or

not.

•Standard Conveyor Widths: 800, 1000, 1200, 1500 mm

• Group Aligning Unit: pneumatic or servo driven barrier

•Row Distribution Unit: Conveyor with Lower outlet and hinge

•Outlet Conveyor: Outlet mobile conveyor with wheels for easier maintenance and cleaning

• Intermediate stoppage belt to set the product flow.

General Characteristics

•Easier and faster maintenance and cleaning

• Polyurethane belt material conforming to food sanitary regulations

•Single type belt drums to reduce different part numbers

•All components in contact with the product are made of stainless

steel AISI 304

•Safety Windows to get Access to any point in the production

flow zone

•At each belt cross section stainless steel pans

Stock belt systems; These are the systems which prevent pro- duct

overflow in packaging lines. It is a belt system which can only move

forward-backward.

General Characteristics

• At every performance change of the packaging machine products

are stocked and thus overflow is prevented.

• When the production is on hold the product on the belt can be

auto- matically or manually fed back according to the customer requirement

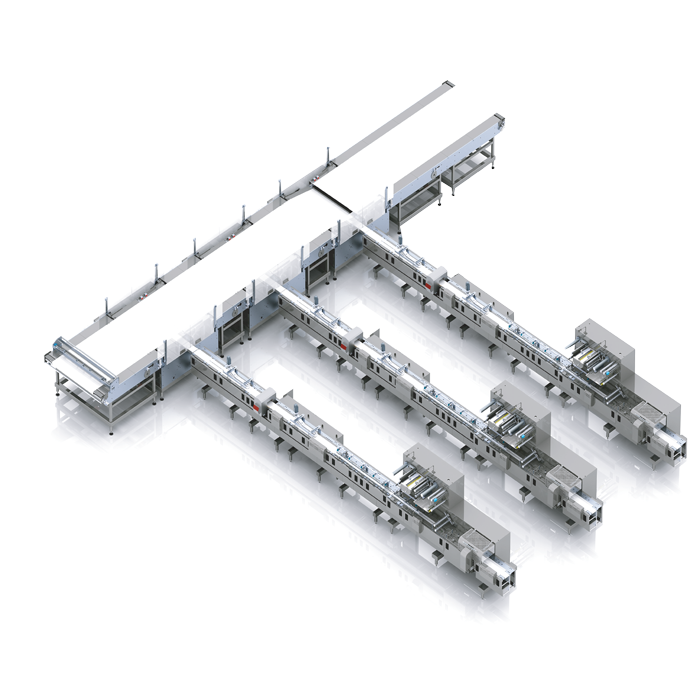

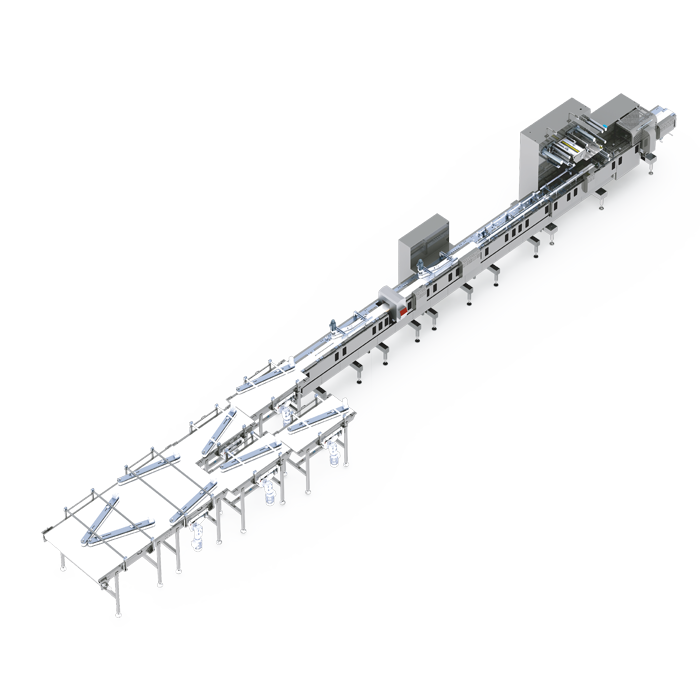

The products spread on a conveyor in rows or unevenly are

divided into separate lines with the help of guides placed on the

belts under a speci- fic angle. Thereafter the products are gathered

in rows thanks to the driven

belts installed with a certain angle. The product rows in lines, are transferred

to the main belt carrying products to the packaging machines which

also contains

a lot of directing sections Distribution-feeding system is generally used for

products coming from filling or enrobing lines This system divides the product flow

in line with the number of machines which need to be fed. This is made by increasing

the speed of belts which are equipped with plates on which fixed dividers are placed.

The products then are

transferred vertically to a faster belt located onto the motor driven belts. This enables a

distri- bution of products coming in rows according to the related machine

Advantages

• Modular design, assembly according to the special customer requirements

•Easy aftersales service and safety

•Open and hygiene, chassis type structure

•Easier and faster belt change

• Solid structure

General Characteristics

•Polyurethane belt material conforming to food sanitary regulations

•Single type belt drums to reduce different part numbers

• All components in contact with the product are made of stainless steel AISI 304

• At each belt cross section stainless steel pans