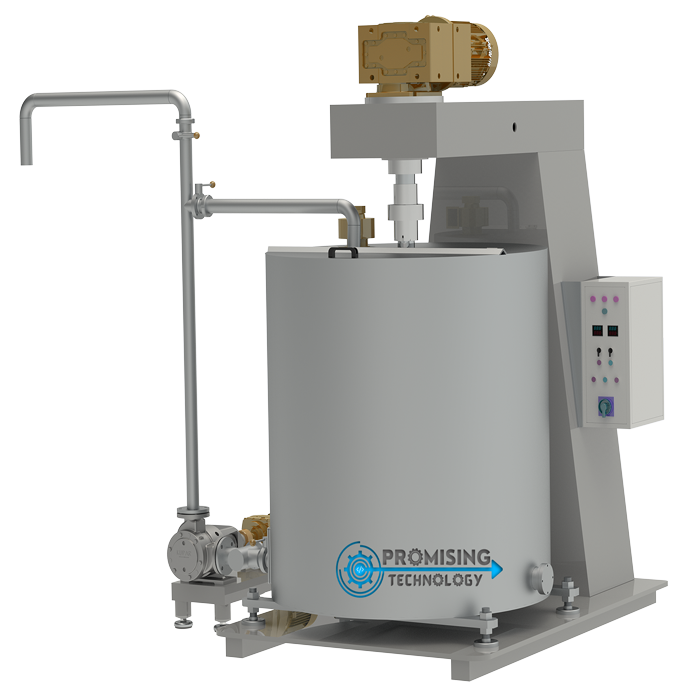

It is a tank where preliminary of nougat batter is made and prepared homogeneously for cooking. It can circulate in itself with the help of a pump. Outer section of tank is heat-walled. The product recipe that can be adjusted from the control panel automatically adjusts the amount of product to be transferred from the tank or to be taken into the tank by means of loadcell and electronic valves. The inner part of the tank and the pipe connections can be easily washed and drained by the rotating water heads inside the boilers.

It’s tank that is used for stocking of ready to cook nougat batter. When the product is desired to be used, it is transferred to the cooking unit by means of pumps. Mixers are available in order to protect homogenous structure. The product recipe that can be adjusted from the control panel automatically adjusts the amount of product to be transferred from the tank or to be taken into the tank by means of loadcell and electronic valves. The inner part of the tank and the pipe connections can be easily washed and drained by the rotating water heads inside the boilers. Reservoirs is heat-walled.

In order to prepare the nougat product, the glucose product is kept ready to use in this tank at a certain temperature. Gluacose is transferred to desired tank in needed. Outer part of reservoir is heat-walled.

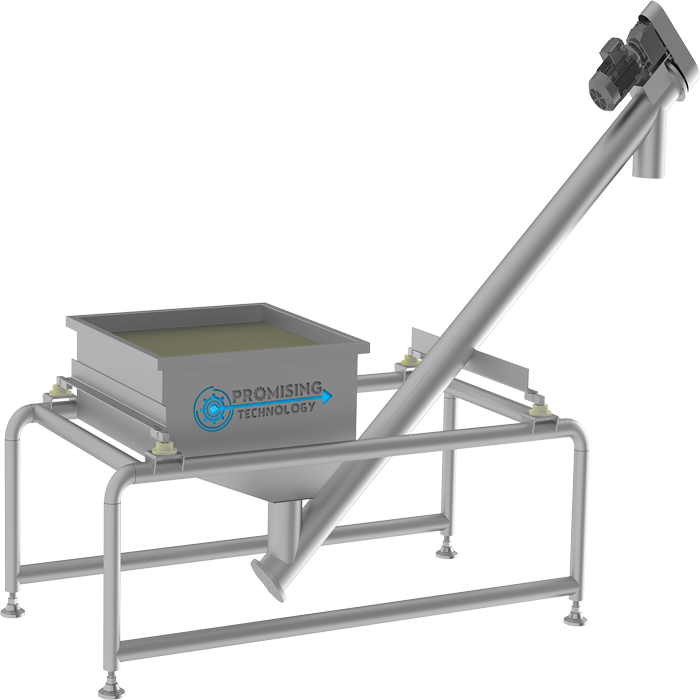

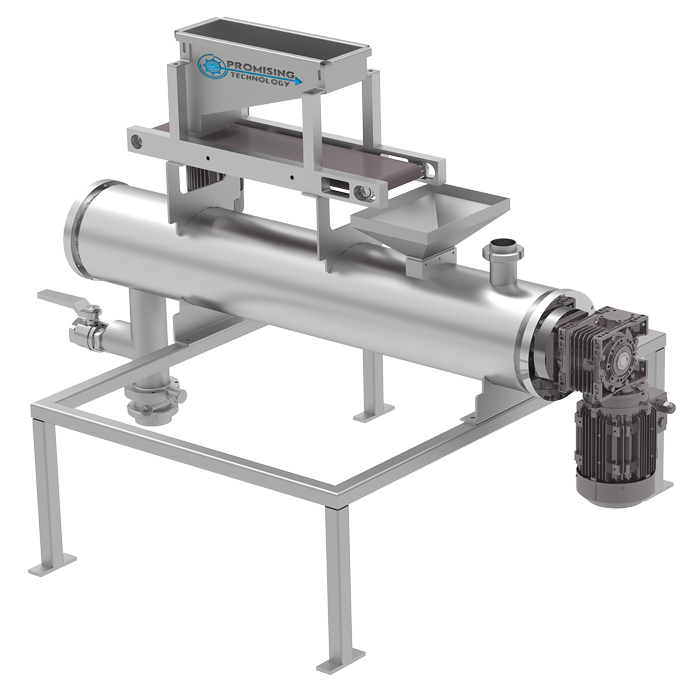

It is a helix system used to transfer the desired sugar into the desired boiler. Sifter is available in reservoir. The reservoir is connected to the chassis with loadcell connections in order to determine the quantity of product. It can be manufactured desired capacity.

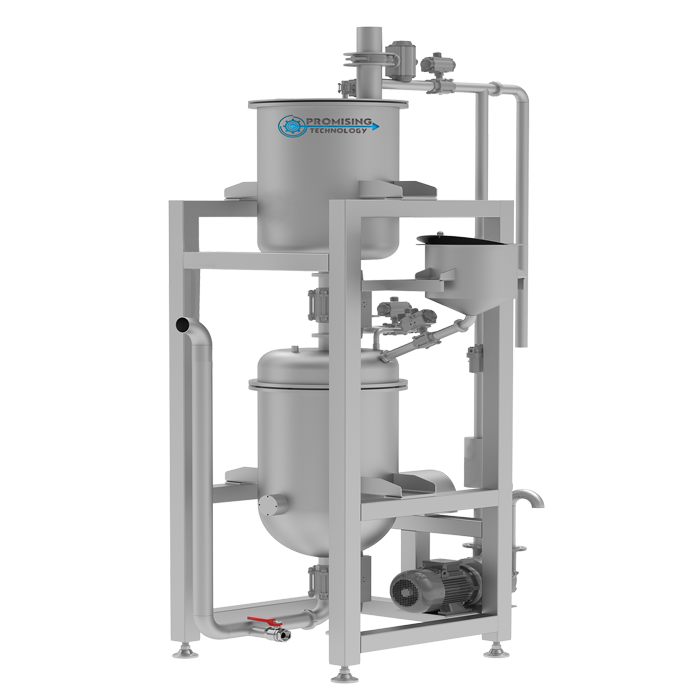

It consists of two main reservoirs.

Cooking reservoir cooks the syrup with

steam. It can work under atmospheric

pressure and vacuum. Its high volume

allows the product to foam without the

risk of being absorbed in by the vacuum

pump. The second reservoir is used for

ventilation. The cooked and vacuumed

product is placed in the scrambling

reservoir and mixed together with the

scrambling substances (egg solution).

System can do steady or non-stop product

processing.

Product inlet and outlet, chimney, steam

inlet, air and egg inlets are done with actuated

valves. Product observation windows

and pressure indicator are available

on the machine.

It is the unit that prepares and stores the egg solution required for nougat. The mixer makes solid materials such as (glucose, fat, sorbitol, salt, etc.) into homogeneous liquid for use in the pre-preparation tank. It is the tank that standing and transfer the egg solution to the turbo mixer automatically when desired and the tank body cooling system is provided with central cold water. It is designed in such a way that no product remains. Mixer motor available on the machine. It contains weighing unit. There are stainless anchors and arms that mix the material homogeneously. Washing head are available on machine.

It is the unit that prepares and stores the oily mixture solution required for

nougat.

The mixer makes solid materials (fat, starch, milk powder, cocoa,

PST, etc.) into a homogeneous liquid for use in the preliminary tank.

It is the tank that keeps the oily mixture solution ready and automatically

transfers it to the solid mixer at any time, the tank

body heating system is provided with central hot water.

It

is designed in such a way that no product remains.

Mixer

motor available on the machine.

It contains weighing

unit.

There are stainless anchors and arms that mix

the material homogeneously.

Washing head are

available on machine.

It is the machine which provides the homogeneous mixing of the oily solution to the cooked and aerated product. It is the machine where the surfaces in contact with the product are manufactured of stainless steel and the wall heating is done centrally. The chassis fittings is manufactured from platinum and painted. The mixer operates bidirectionally. Overturn transaction is done with reducer.

It is the unit that prepares and stores the milk solution needed for caramel. The mixer makes solid substances (sugar, glucose, milk powder) into homogeneous liquid for use in the preliminary tank. Body heating system is provided with central hot water. It is designed in such a way that no product remains. Resistance and mixing motors are available on machine. Equipped with weighing unit. There are stainless anchors and arms that mix the material homogeneously.

It is a machine that mixes the raw materials required for caramel (fat, milk powder, sugar, lecithin, aroma, vanilla etc.) in a homogeneous way and makes it into liquid. Body heating system is provided with central hot water. It is designed in such a way that no product remains. Resistance and mixing motors are available on machine. Equipped with weighing unit. There are stainless anchors and arms that mix the material homogeneously.

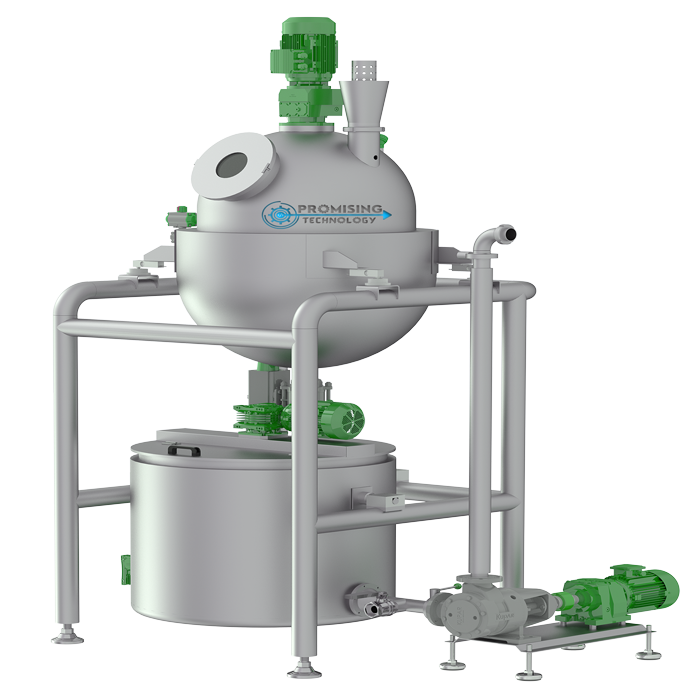

It consists of two main reservoirs. Cooking reservoir cooks the caramel by steam. Specially designed mixers and scrapers are available for faster cooking and non-burning of the product. The system can process the products continuously or intermittently. Product inlet and outlet, chimney, steam inlet is provided by actuated valves. Product observation windows and pressure indicator are available on machine. Second reservoir is 300 kg capacity and heat-walled. The inside of the boilers and the pipe connections can be easily washed and drained with the rotating water heads inside the boilers.

It is a tank in order to keep the cooked caramel product ready for use. The outer part of the reservoir is heat-walled. There are stainless anchors in it to maintain the homogeneity of the product. The product can be transferred by means of the pump when it is desired to be used. It is completely manufactured by using stainless steel material.

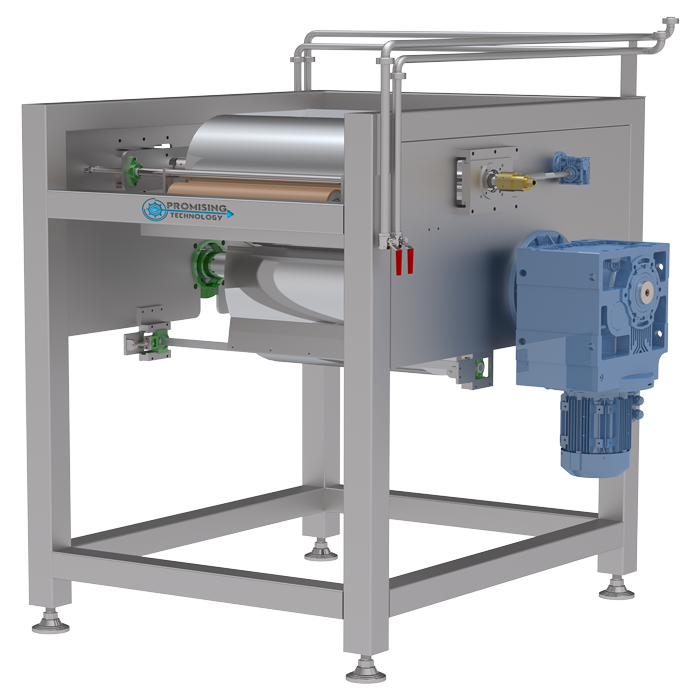

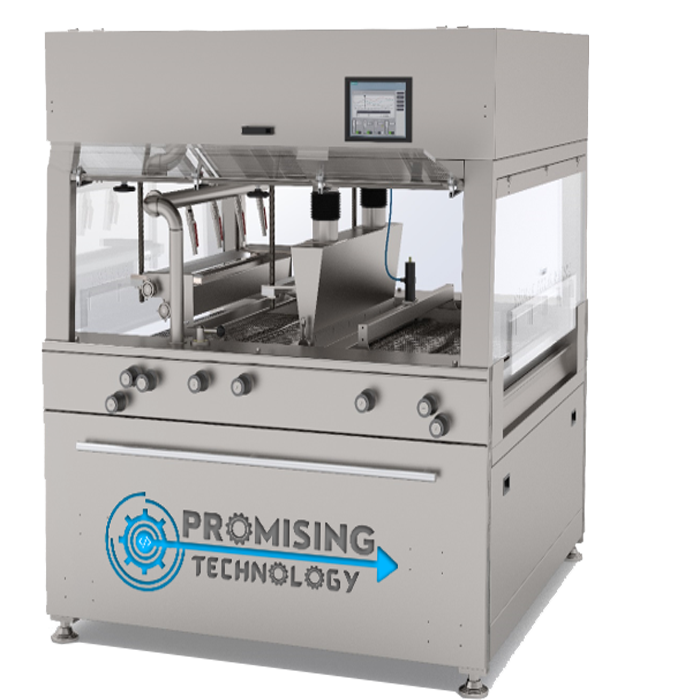

This machine allows the cooked caramel to be fed and shaped directly into the cylinder reservoir without pre-cooling. Both cooling and forming are completed with one machine. Easy to adjust the thickness of the caramel. . Since no force and pressure are applied to batter while in process, the specific weight and structure of product is not changed. It is designed in such a way that variety turns can be done easily without requiring a hand tool. It can shape the caramel in which granula such as nuts and peanuts to be mixed. It can be designed from 300 mm to 1200 mm according to the capacity. It works synchronized with cooling tunnel and other machines.

This machine allows the cooked and aerated batter to be fed and shaped directly into the cylinder reservoir without pre-cooling. Both cooling and forming are completed with one machine. Easy to adjust the thickness of the nougat. Since no force and pressure are applied to batter while in process, the structure of the products such as cereal or aerated is not changed. Special lubrication system is available to prevent product adhesion. By adding comb on machine , the product shaped like wick can be produced. It is designed in such a way that variety turns can be done easily without requiring a hand tool. It can be designed from 300 mm to 1200 mm according to the capacity. It works synchronized with cooling tunnel and oth er machines.

It’s used for distributing nut-peanut etc. product into the nougat,- caramel and crokan homogenously. Reservoir is available for nut-peanut. Outer part of helix is heatwalled. It is a multi-purpose machine that can make precise sprinkling with almost all kinds of granular products. It is designed to enrobe and enrich your products with various grains such as hazelnut, puffed rice, coconut, sesame, granule, starch. Thanks to its special band system, the sprinkling process is carried out both softly and precisely. Via this special system, it does not harm the structure of the sprinkled flavor. It is easy to clean by means of its hygienic and simple mechanical construction and continues to serve for a long time with low and short maintenance. Transportation and installation is also extremely easy.

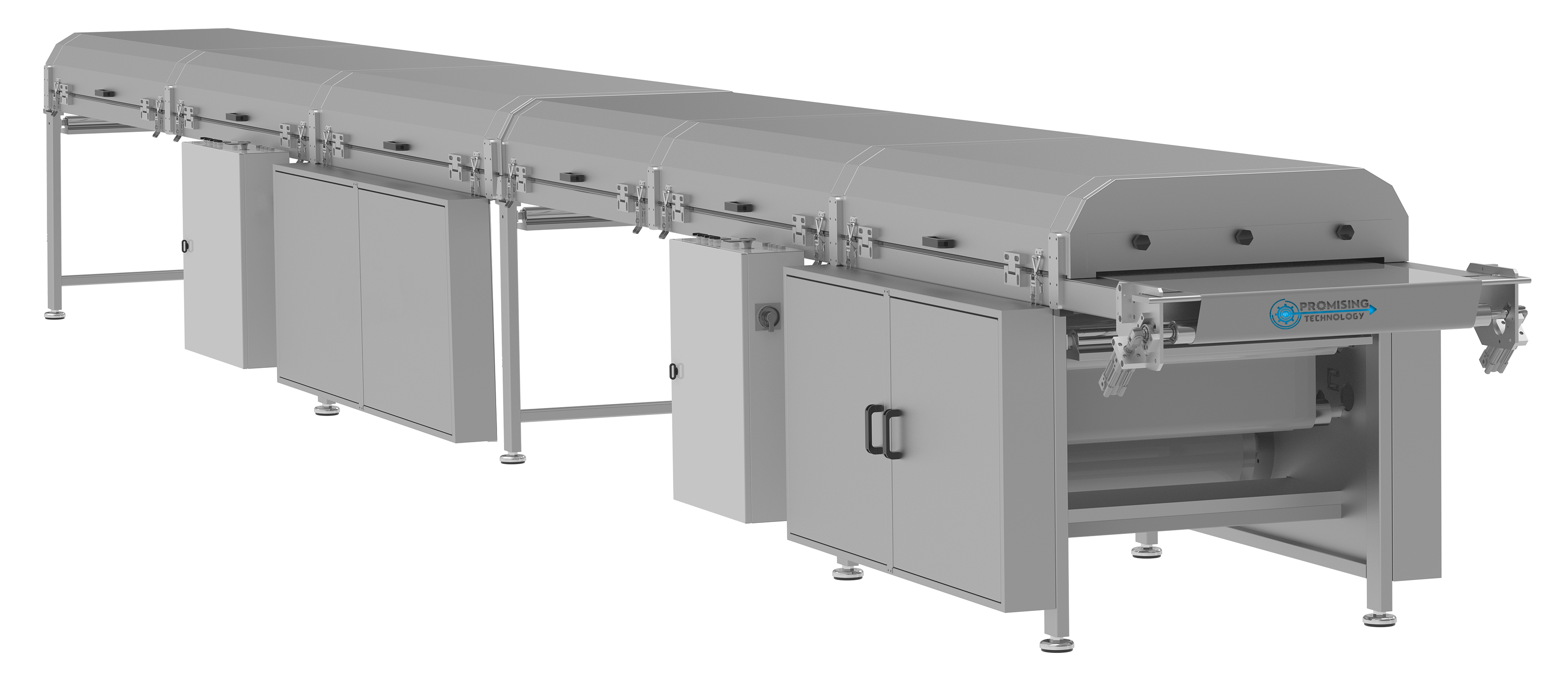

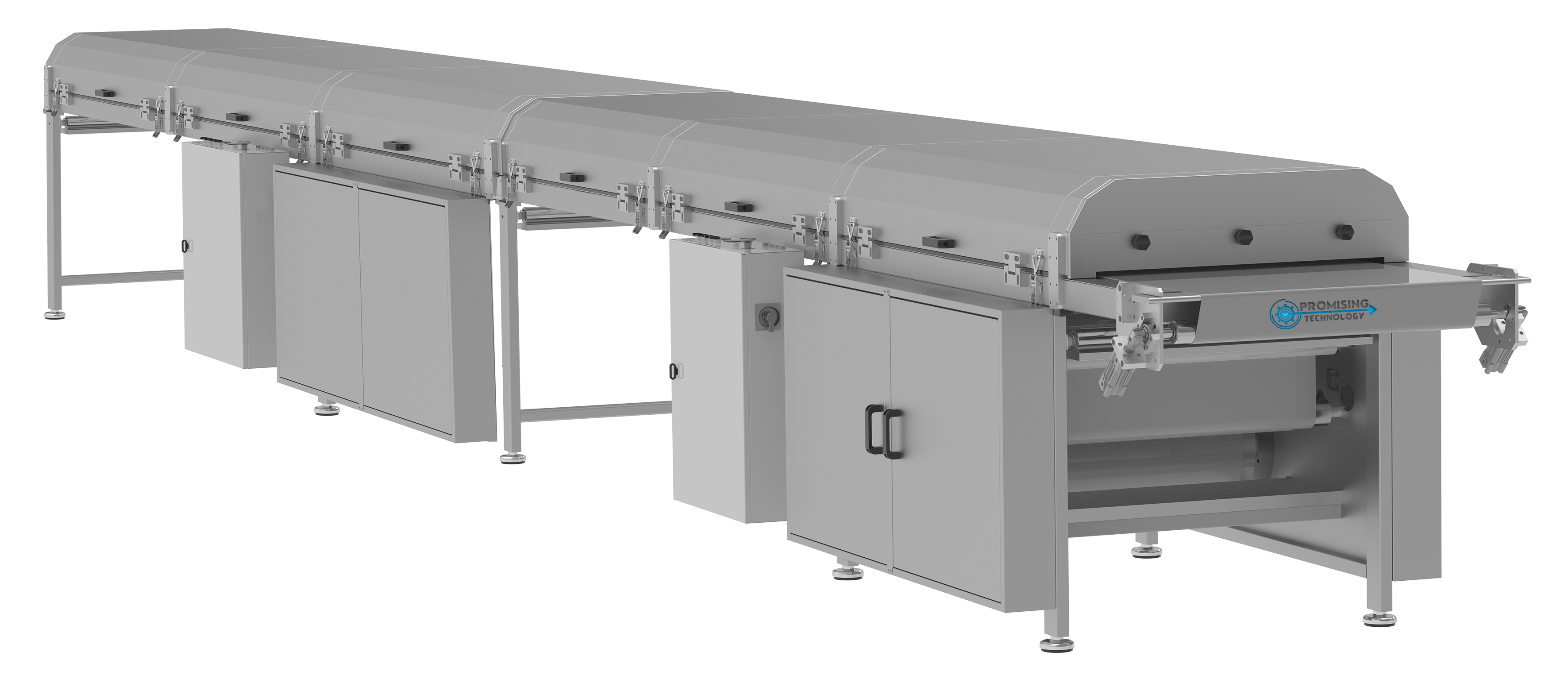

It is a machine used to cool the products laid by nougat cylinders and caramel cylinders. Watery cooled, airy cooled and rollbond system are available. The temperature of the product is reduced by circulating cold water at the bottom of the tunnel. Adjustable to desired lengths. It is very easy to clean thanks to the caps that can be opened in both directions. The band can be precisely adjusted via the band guiding mechanisms at the entrances and exits of the tunnel. The refrigerating unit can be controlled on both sides and independently.

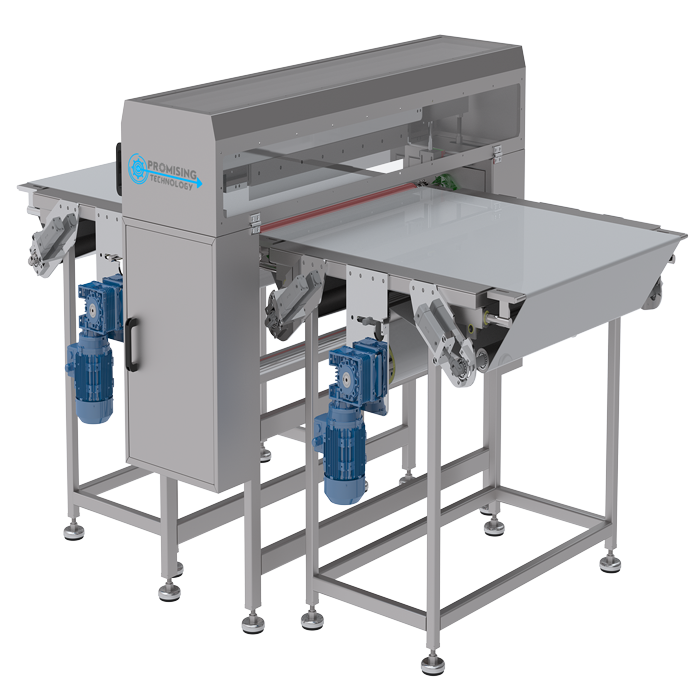

It’s a machine that is used for making the product which is shaped, ideally cooled and laid like carpet into wick by slicing. It allows cutting of frozen nougat and caramel in desired width. Slicing is done with special circular blades of 250 mm diameter. The circular blades have scrapers and a lubrication unit. Blades and scrapers are manufactured stainless steel materials. Changing varieties is so easy. The scraps coming out both sides of cutting are removed automatically with conveyor band.

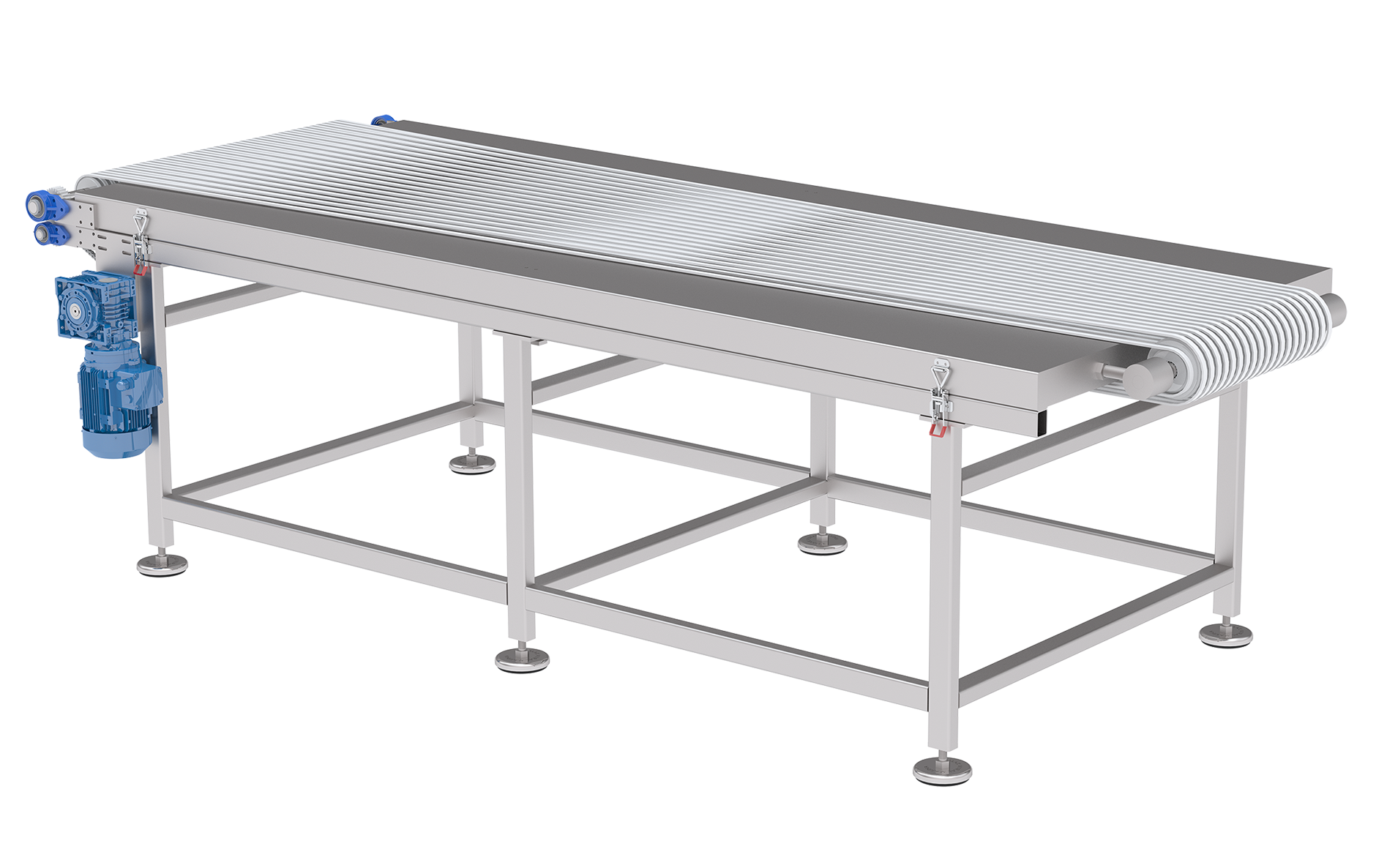

It is a machine that separates the sliced product to a certain extent and prevents it from sticking each other again. Separation is carried out with special imported belts. The top table is designed to be easily dismantled and installed for variety changing.

It is a machine that cuts the length of hard or soft products to the desired extent and separates them into lossless pieces. It makes cutting with special production knife. The cutting blades have a scraper and lubrication system. In this way, the knife is cleaned and lubricated in every cut. It is equipped with servo motor and thus ideal cutting is done. Input and output banda re PU compatible for food regulations. Cutting length can be adjusted automatically from PLC screen.

It is a machine that makes fats to liquid for use in preparation of wafer, chocolate, caramel. There are serpentines in which hot water is circulated. The melted oil can be easily transferred to the desired machine by means of a pump.

It’s a boiler that all the raw materials needed for the chocolate mixture are collected. It aut omatically adjusts the amount of product to be taken into the boiler with the help of loadcell and electronic valves. The reservoir is heat-walled and the hot water is continuously circulated by means of a circulation pump. The mixers are driven by two separate motors. It can transfer the prepared chocolate mixture to the chocolate mixer by means of pumps.

It is a machine used to make thin and mix the chocolate mixture to a more homogeneous structure. The reservoir is heat-walled and the hot water is continuously circulated by means of a circulation pump. The product is accessed to the desired fineness with the help of steel balls in the reservoir. Strainer and magnets are available at the reservoir outlet. The product can circulate by means of a pump. The prepared chocolate mixture can be transferred to the chocolate stock tank by means of pumps.

It is the tank used to stock the chocolate prepared in the chocolate mixer. There is a continuous mixer system in order to keep the homogenous structure of the chocolate waiting for use. If desired, it can be transferred by means of pumps. The reservoir is heat-walled and the hot water is continuously circulated by means of a circulation pump. It can be manufactured in different capacities as per the request.

It is a machine using for enrobing chocolate to products such as wafers, cakes and biscuits. It is designed according to work both real and cocoline chocolate enrobing. Machine is designed adjustable, if required , just bottom , just top and completely enrobing options can be done. Bandwidth can be manufactured in desired dimensions. It can be easily controlled from the touch panel on the machine.

It is a machine used to cool the products coming out of chocolate enrobing machine. Watery, airy cooling and rollbond systems are available. Adjustable to desired lengths. It is very easy to clean thanks to the caps that can be opened in both directions.